Near-miss: Personnel almost caught between crane house and scaffold pipe

- Safety Flash

- Published on 19 July 2011

- Generated on 11 February 2026

- IMCA SF 07/11

- 2 minute read

Jump to:

A Member has reported an incident in which someone was almost caught between a crane housing and a scaffold pipe.

The incident occurred when a non-destructive testing (NDT) inspector was conducting an inspection at the stern of the crane, outside on the roller level.

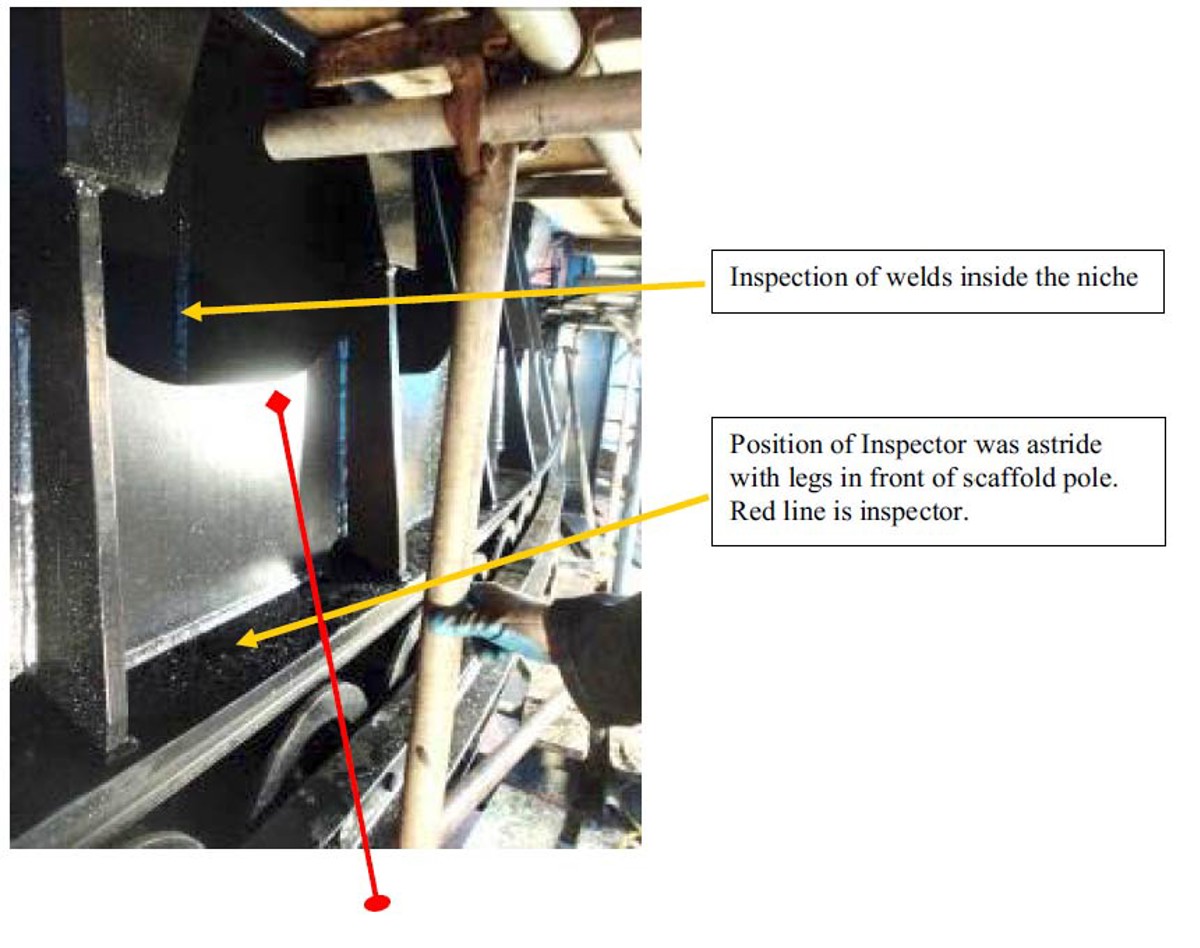

The access was from the scaffold around the crane. The inspector was positioned at a beam, behind a vertical scaffold pole. He had just finished the inspection of the welds and stepped back from the crane housing onto the scaffold platform when the crane started slewing.

A deck supervisor spotted the inspector on the scaffold platform and asked him what he was doing. Immediately the deck supervisor ordered the crane driver to stop the crane. Had the crane started to slew earlier, then he could have been caught between the crane housing and the scaffolding pipe.

fig. 1: site of the incident

What were the causes?

The following direct causes to the incident were identified:

- The crane operator was not informed at the start of the work.

- There were inadequate guards or barriers.

- Log out tag out procedures were not applied.

Subsequent to further investigation the following points were noted:

- A ‘last minute risk assessment’ by the NDT inspector did not reveal the actual risks owing to his lack of experience, and he did not notice that in case of crane slewing the scaffolding would rotate independently from his work spot.

- There was inadequate initial instruction, and information was not communicated properly to all the involved parties.

- The toolbox talk process was not conducted in accordance with established procedures.

- The work process was discussed without involvement of all parties (deck crew/crane operator).

- The wrong crane operator was informed before the operation took place.

- This was done during an accidental encounter in the accommodation.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.