Crewman fatally injured during mooring operations

- Safety Flash

- Published on 10 November 2010

- Generated on 23 January 2026

- IMCA SF 07/10

- 2 minute read

Jump to:

A Member has reported an incident in which a crewman suffered fatal injuries after being hit by a snapping chain and mooring rope connection.

What happened?

The incident occurred during mooring operations whilst manoeuvring two vessels together.

At the project worksite, one vessel was being manoeuvred towards the appointed workplace using a mooring line and winch. Rigging was slackened by the winch on one vessel; then the angle between the two vessels increased, which caused an increase in tension. At that moment the chain snapped at the pad-eye connection on one vessel, and a deckhand was hit by the chain and mooring rope as it swung across the deck causing fatal injuries.

Swipe to see next image

Our Member’s investigation revealed the following:

- The deckhand moved into ‘in the line of fire’ in the path of the breaking chain.

- The breaking strain of the equipment used was underestimated in relation to the work being undertaken.

- Limited communication and poor sight lines between vessel masters, winch operator and deckhand were a factor.

Our member made the folllowing recommendations:

- Thorough revision of company procedures and risk assessments for this task, including types of connection, winches and towing equipment, and communications.

- Ensure all persons involved are involved in toolbox talks before this task.

- Check certification and fitness for use of all lifting and towing equipment (bollards, ‘bridle’ connection, wires, ropes).

- Establish clear communication (radio, signals and visibility) between the master of the towing/pushing vessel, the crane or winch operator and any personnel on deck.

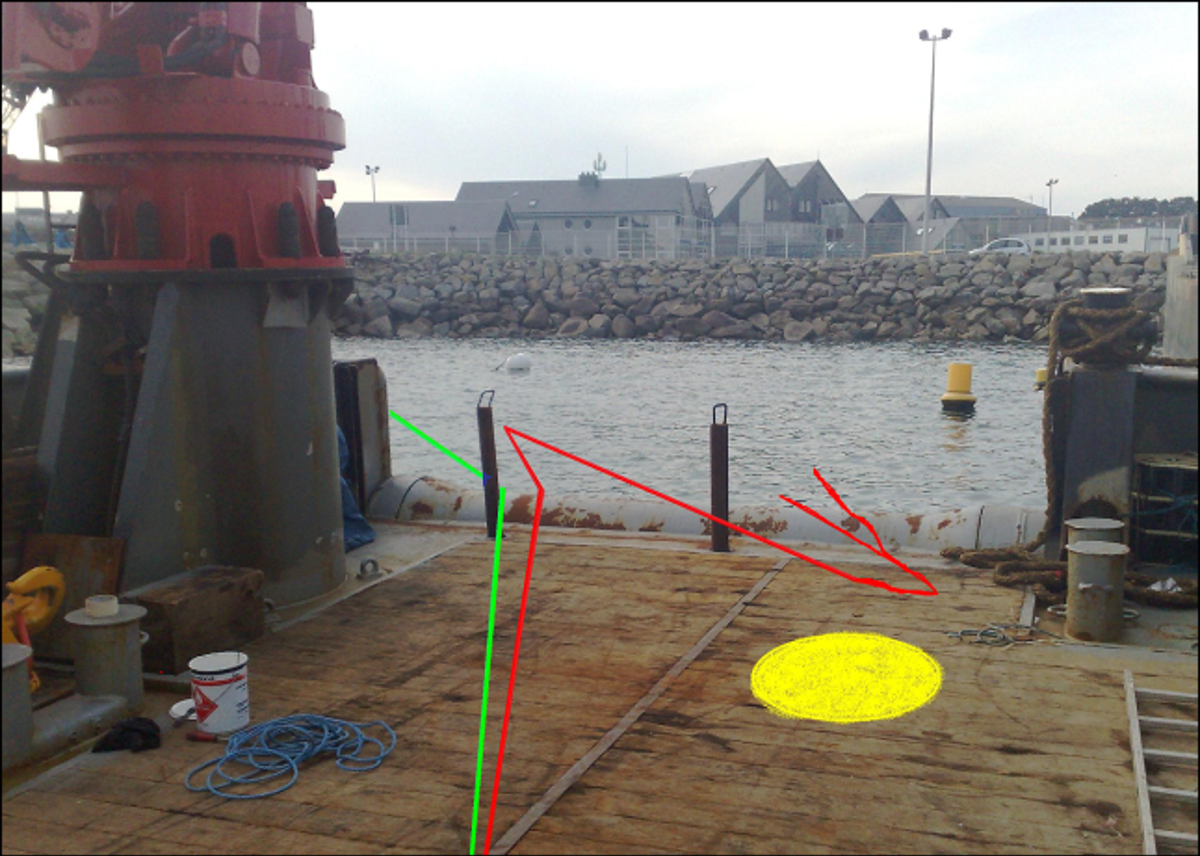

Figure 6 -Scene of incident (green line indicates towing line, red line indicates snapped towing line, yellow area indicates position of crewman)

Our member drew the following conclusions:

Perhaps the most important point highlighted by our Member is that crew should take great care in their movements on deck in relation to possible danger from equipment failure, particularly with regard to ropes, towing and rigging equipment.

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.