Near miss: Foreign body in diver’s helmet, resulting in fall of gas pressure

- Safety Flash

- Published on 27 February 2023

- Generated on 8 February 2026

- IMCA SF 06/23

- 2 minute read

Jump to:

During a routine dive at a depth of 18m (60’), the diver reported to the Dive Supervisor a drop in breathing gas pressure.

What happened?

The diver switched to bailout gas which did not solve the problem.

The diver opened the free flow which increased gas pressure to a suitable level.

The diver left the sea bottom and returned safely to the vessel deck.

Upon removal of the diving helmet (a Kirby Morgan 37) a foreign body was found in the demand valve chamber section of the helmet regulator.

What went right?

The diver remained composed and took the correct emergency actions.

What went wrong?

A foreign body found its way undetected into the helmet during pre/post-dive cleaning. It is thought that the likely cause was the foreign body – a small shard of plastic – entered the regulator body and restricted the action of the lever arm.

- The bowl or utensil used for cleaning helmet parts was an old and broken plastic pot.

- The foreign body was identified as being part of the old and broken plastic pot used as a cleaning utensil.

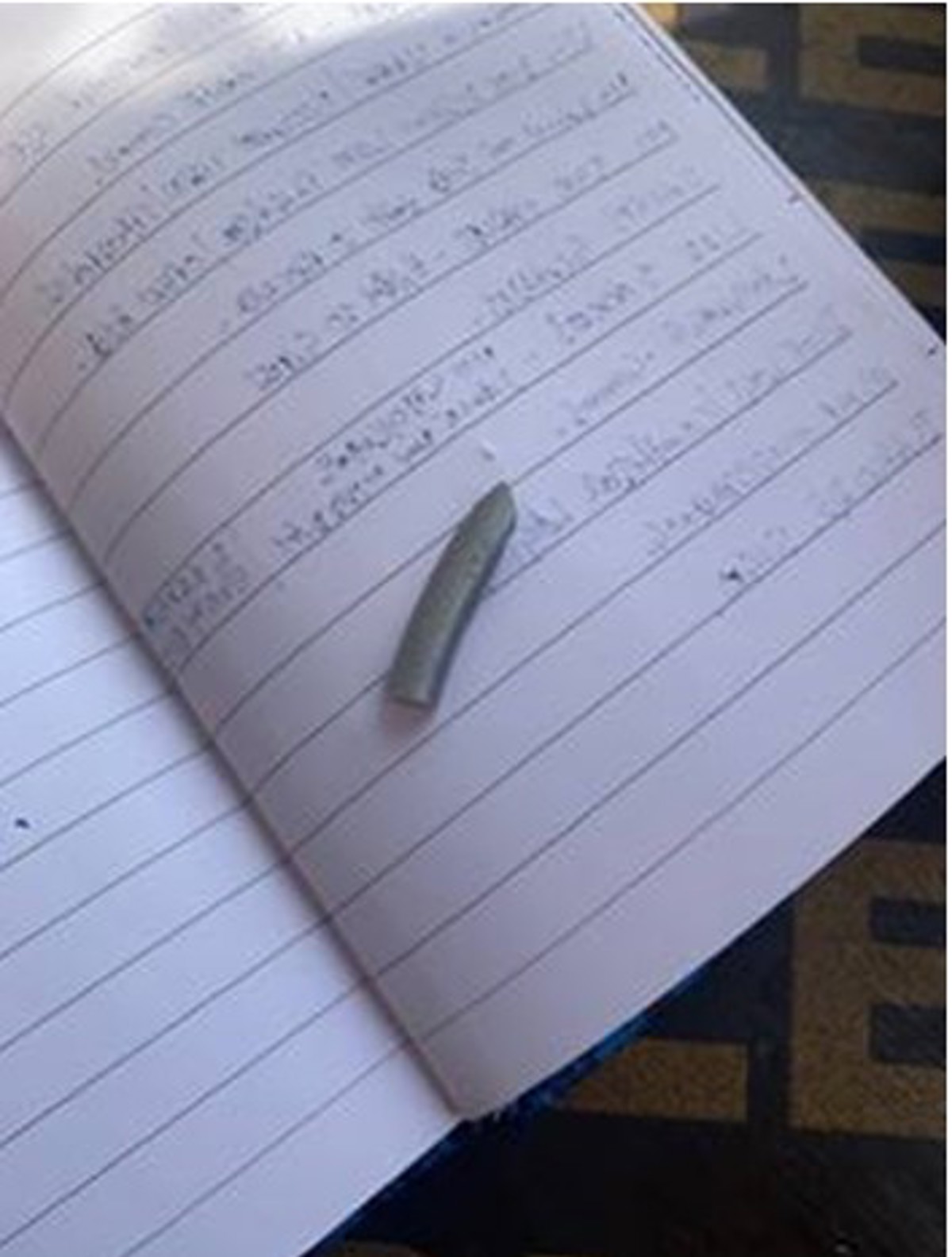

Plastic pot used to wash the internals of the hat

Foreign body from the plastic pot broken off (22 mm)

What was the cause?

Inappropriate or sub-standard cleaning technique for an item as vital as a diver’s helmet

Lessons and actions

- Consider how something so minor could have such an impact on a diver’s gas supply.

- Reiterate the importance of pre-dive checks and of the need for absolute cleanliness in divers’ life-saving equipment.

- Our member introduced spray bottles to eliminate the chance of particles entering the helmet during cleaning.

Related safety flashes

-

IMCA SF 06/22

11 March 2022

-

IMCA SF 30/21

8 November 2021

-

-

IMCA SF 26/21

22 September 2021

-

IMCA SF 12/18

14 June 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.