Get it fixed!! Deteriorated seals on emergency hatch

- Safety Flash

- Published on 11 March 2022

- Generated on 2 March 2026

- IMCA SF 06/22

- 2 minute read

Jump to:

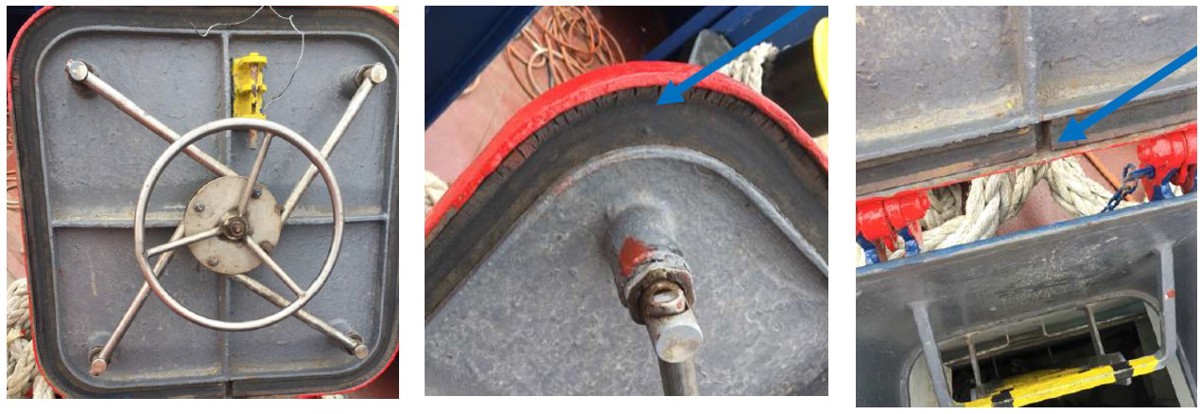

Deteriorated seals were found on a number of hatches during an inspection.

What Happened?

During an inspection of a vessel as a part of the 5-yearly docking, deteriorated seals were found on a number of hatches.

Preliminary investigation was conducted and after crew feedback, it was revealed that the crew had observed this unsafe condition some while ago, ordered and received new seals, but had continued to operate with no action, waiting for docking in order to replace deteriorated seals etc.

Hatch seals perform a vital role in a wide variety of marine applications. The hatch seal ensures that no liquid or gas is able to enter the vessel. After a period of use seals can deteriorate and become worn which reduces potential sealing properties. In this case, there was the risk of potential seawater leakage to the engine room had no action been taken.

What went wrong? What was the cause?

- Lack of risk perception and lack of timely action by vessel crew after identifying deteriorated seals – continuing to operate in an unsafe condition, considering waiting until the vessel was docked.

Actions

- “If it isn’t broken, don’t fix it” is a call to inaction – if something needs dealing with, deal with it now, not later.

Related Safety Flashes

-

IMCA SF 12/21

27 April 2021

-

-

IMCA SF 24/20

14 August 2020

-

-

IMCA SF 09/17

3 May 2017

-

-

IMCA SF 07/07

14 August 2007

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.