LTI: Person crushed in watertight door

- Safety Flash

- Published on 16 February 2023

- Generated on 6 March 2026

- IMCA SF 05/23

- 2 minute read

Jump to:

An electrician was crushed and severely injured while working on a watertight door on a vessel.

What happened?

The electrician was evacuated by helicopter.

The incident happened when the door opened unexpectedly, during adjustment of a proximity sensor for the door.

Just before this adjustment, the electrician had closed a ball valve in the hydraulic system, believing this was a safety valve which would prevent the door from opening.

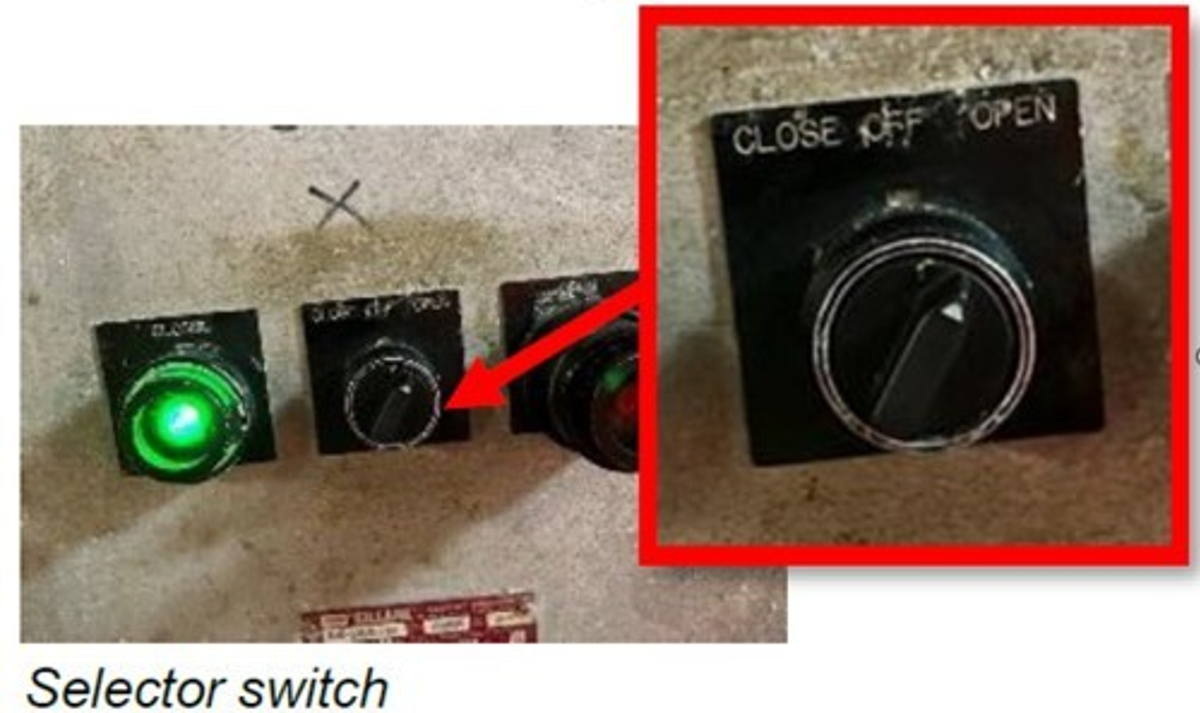

Once working on the system, the selector switch on the primary operating system, which is used to open and close the watertight door, did not return to the neutral position enabling a signal to be sent to the programmable logic controller (PLC).

When the electrician manually aligned the sensor which he had to repair, a signal went to the PLC and the door opened unexpectedly crushing him between the door and the deck.

Fig. 1: Vertical watertight door

Fig. 2: Watertight door opening on dummy (DEMONSTRATION)

What went wrong?

- The system was not isolated at the time of the incident – no Lock Out / Tag Out system was in place.

- There was no request for a Permit To Work (PTW) nor was a Job Safety Analysis (JSA) prepared for the activity.

- The ball valve did not isolate the hydraulic system:

- The ball valve was not a safety valve.

- The ball valve was leaking.

- The ball valve was not a safety valve.

- The door opened when the command “open” came in from the PLC. This command came in because the selector switch was damaged and did not return to the neutral position once released.

- When the door is operated, visual and audible alarms are initiated. The alarms and signals were not fully operational nor working.

Fig. 3: Selector switch was damaged and did not return to the neutral position once released

Lessons learned

- Ensure there is a Permit To Work in place, a Lock Out / Tag Out procedure, and a suitable and sufficient job safety analysis before you start.

- Hydraulic system ball valves are not “safety valves”. Take care that you fully understand what you’re working on, and ensure systems are fully de-energising before putting yourself in the line of fire.

- The switch on the primary operating system was not in working condition but there were not sufficient spares on board to replace them. Sufficient spare parts should be on board, so these can be replaced immediately.

Related safety flashes

-

IMCA SF 06/19

5 April 2019

-

-

IMCA SF 25/17

19 October 2017

-

-

IMCA SF 03/16

27 January 2016

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.