Restricted work case (RWC): Injury to foot caused by moving roller

- Safety Flash

- Published on 10 April 2014

- Generated on 3 March 2026

- IMCA SF 05/14

- 2 minute read

Jump to:

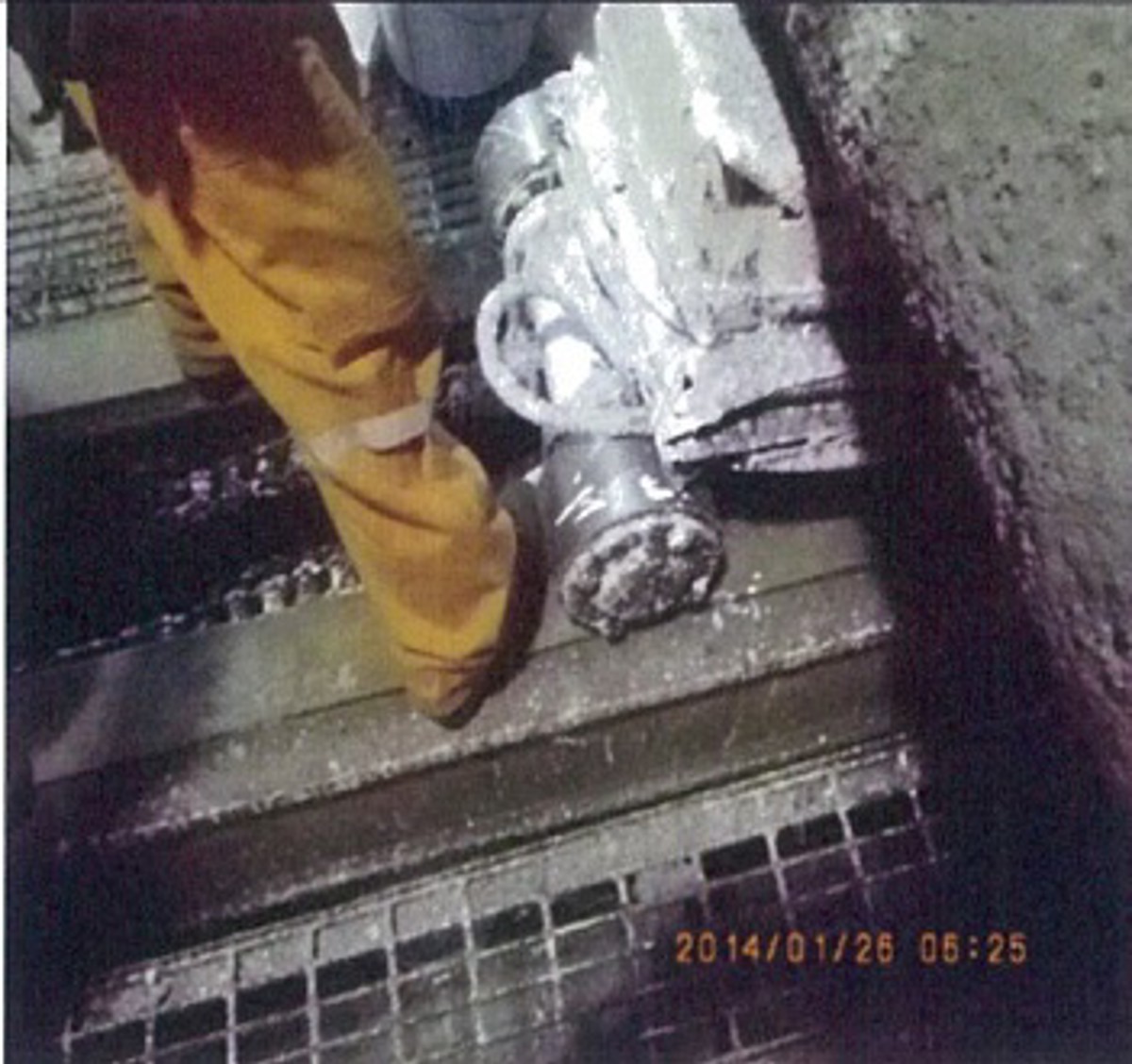

A Member has reported an incident in which a person sustained an injury to his right foot caused by a moving roller in pipe-handling equipment.

What happened?

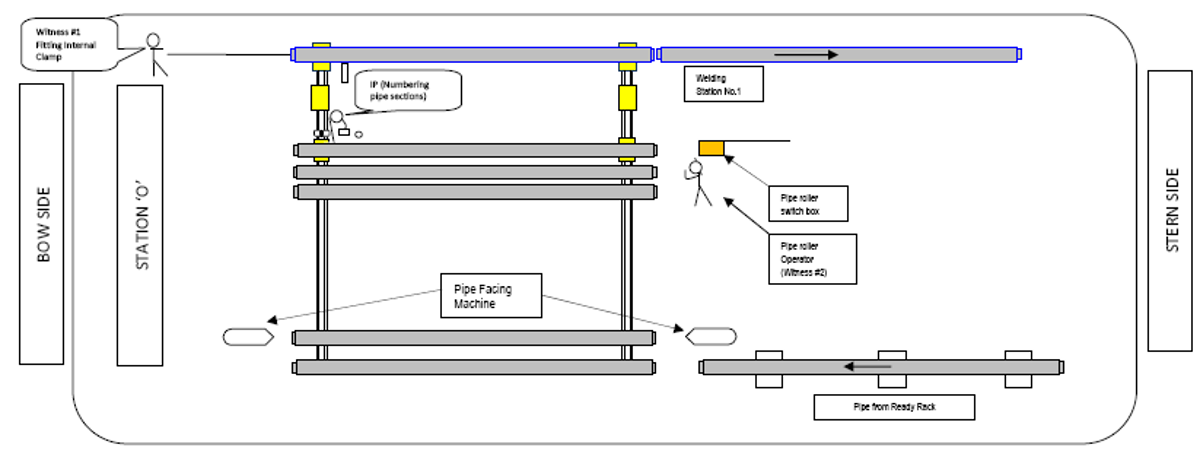

The injury happened when a crewman took a window of opportunity during a short repair period to paint pipe numbers on the ends of the pipes. The operator of the roller did not ensure that the area was clear moving the roller, and the crewman was caught by the roller and sustained a crush injury to the right foot.

The investigation revealed the following:

- Operator operating the roller machines failed to ensure the ramp way/area was clear before activating the pipe transfer machines.

- There was a lack of supervision from the work supervisor.

- The operator of the roller machine was not able to communicate effectively with other workers.

Our member took the following corrective actions:

- The task of numbering of pipes was transferred to another, safer, location.

- An alarm warning system was installed to alert the operator of the presence of personnel in the path of the rollers.

- Signage was installed warning personnel that they were ‘in the line of fire’ in this location.

Related safety flashes

-

IMCA SF 08/06

22 June 2006

-

IMCA SF 10/02

1 October 2002

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.