Unauthorised modification to electrical plant equipment

- Safety Flash

- Published on 19 March 2008

- Generated on 26 January 2026

- IMCA SF 04/08

- 2 minute read

Jump to:

A Member has reported the discovery of unauthorised modifications to electrical equipment used by divers.

What happened?

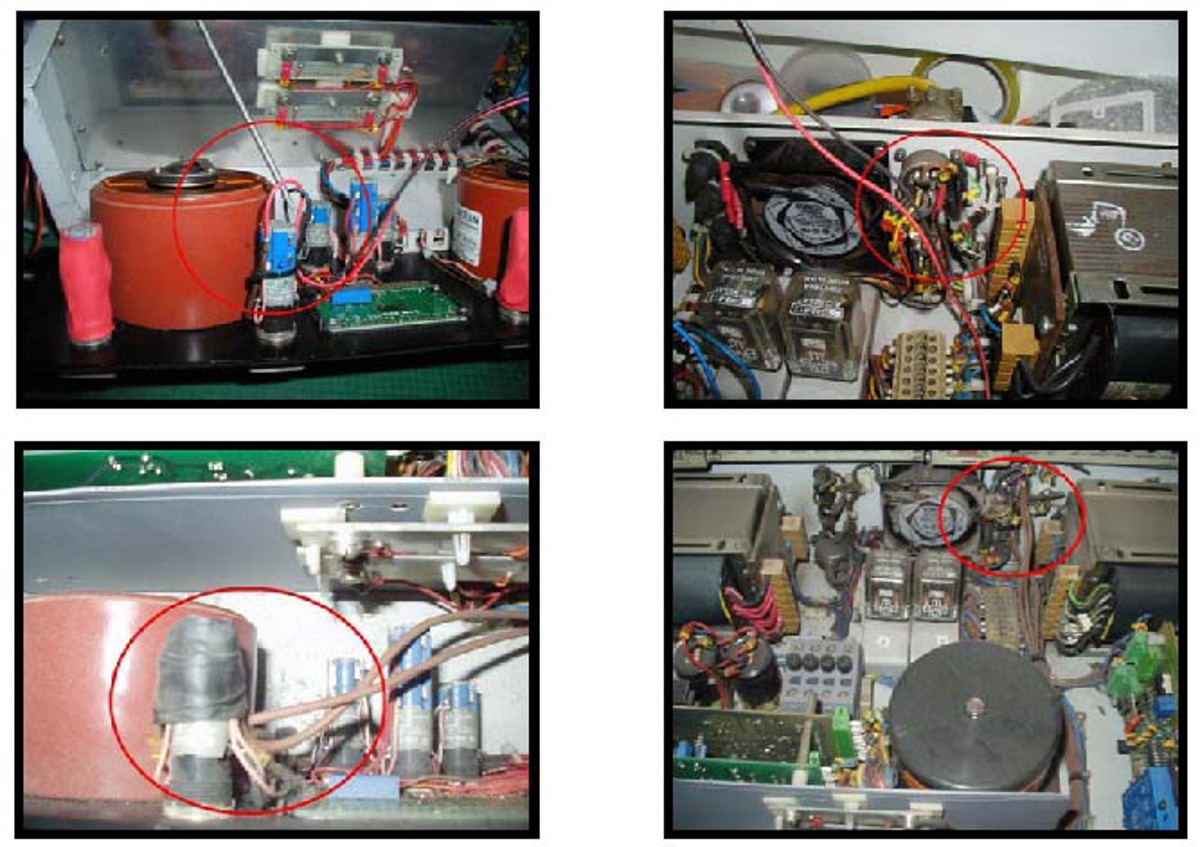

During the onshore refurbishment of two dual diver CLP (camera, light and power) surface control units it was noted that these had been modified offshore to enable the diver’s hat light to be switched on and off remotely from the unit, presumably by the diving supervisor standing at the dive panel. The modifications involved adding wires to the back of the hat light on/off switch on the front panel of the CLP and wiring this through to a pair of unused pins on an output socket on the back of the unit.

The modifications to each of the two CLPs were carried out using a different colour and a different gauge of electrical wire and resulted in 220-240Vac being routed to the output sockets where there is normally only relatively low DC voltage (30-55Vdc). The modifications also changed the connection pins used, altering an internal company standard that has been in place for 20 years. Diver CLP surface control units are intended to be universally interchangeable; these modifications made them suitable only for the job they were used on. Also, the wiring drawings for the units became incorrect as a result of these unauthorised modifications.

Recommendations and actions taken

The company involved recommended that offshore dive technicians and chief engineers be reminded that no modification to any item of plant is attempted without first asking for and receiving the express permission of the appropriate company authority onshore. The units were rewired back to the company standard and the onshore electronics technicians were warned to be aware of the modifications seen and include this as something to verify during all future checks.

The company also recommended investigation into whether or not there is a common requirement to switch on and off the divers’ hat lights remotely and also to investigate the possibility of retro-fitting of a low voltage remote to the diver CLP surface control units to permit this.

Unauthorised modification to electrical equipment

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.