Corrosion: Failure of bolts on a cargo barge bollard

- Safety Flash

- Published on 27 February 2019

- Generated on 13 February 2026

- IMCA SF 03/19

- 2 minute read

Jump to:

What happened?

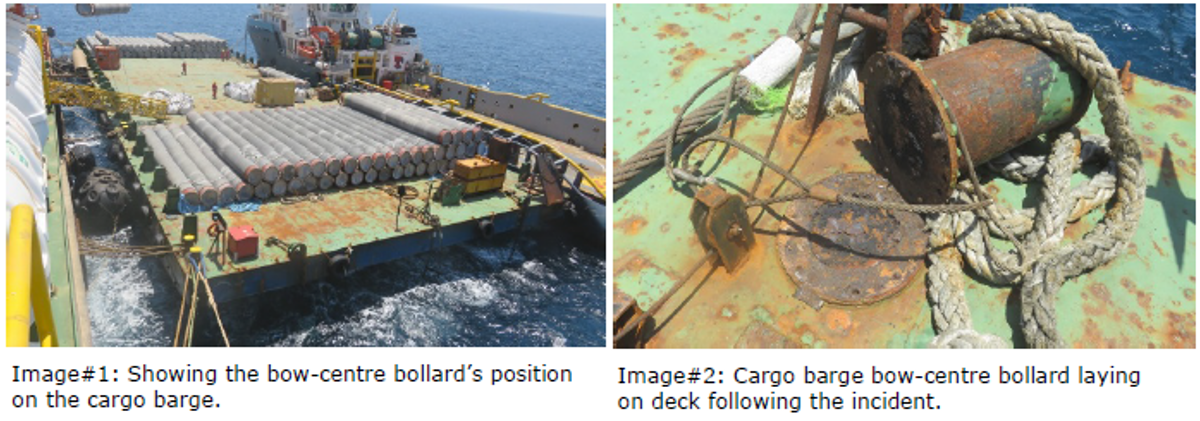

During pipelay operations a cargo barge was moored port side to the pipelay vessel to enable pipe loading. Mooring lines were secured to the cargo barge’s bow, stern and mid-ships bollards. Due to adverse weather, an additional mooring line was attached to the centre bow bollard of the cargo barge. As this additional mooring line was picked up by the vessel winch, the centre bow bollard ‘toppled over’. There were no personnel in the vicinity of the bollard during this operation.

An all-stop was called and the winch was operated to slacken the mooring line. Upon inspection, it was found that the bollard was in very poor condition and that all of the securing bolts were corroded, to the extent that they were not connecting the bollard to the deck of the barge.

What went wrong?

- This centre bollard was not designed to be used for mooring operations. Instead, it was in place for the securing of the barge’s tow bridle, when not in tow. This particular bollard, rated 25 T SWL, was not fit to perform its designed purpose and hold any weight.

- The condition survey for the barge did include inspection of all mooring bollard but not the bow centre bollard which was not designed or planned for use.

- NB: The classification certificate for the barge was valid and class inspection conducted in March 2017.

What lessons were learned?

- Cargo barge mooring arrangements should be properly engineered, and clearly defined in any procedures, with usable mooring points clearly identified.

- Cargo barge condition survey process should include visual inspection of all items to be used during barge operations.

- Bolted load bearing structures, exposed to the marine environment, should be subject to detailed inspection such as removal and inspection of the bolted connection, which may have experienced corrosion and rapid degradation even within the certification validity period.

Related Safety Flashes

-

IMCA SF 04/18

20 February 2018

-

-

IMCA SF 22/15

15 December 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.