Near miss: Unidentified differential pressure led to diver’s umbilical getting trapped

- Safety Flash

- Published on 13 February 2017

- Generated on 9 January 2026

- IMCA SF 03/17

- 3 minute read

Jump to:

A member has reported an inshore diving near miss incident in which a diver’s umbilical became trapped and subsequently damaged – no divers were injured.

What happened?

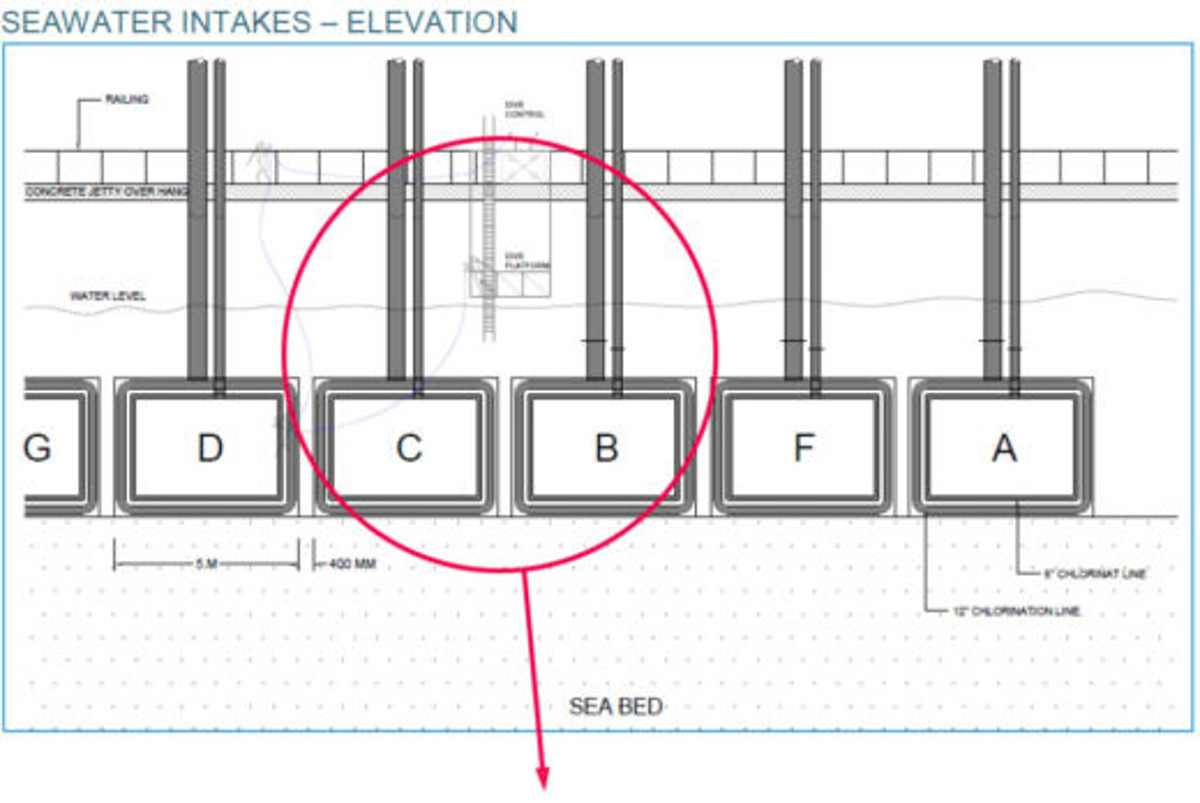

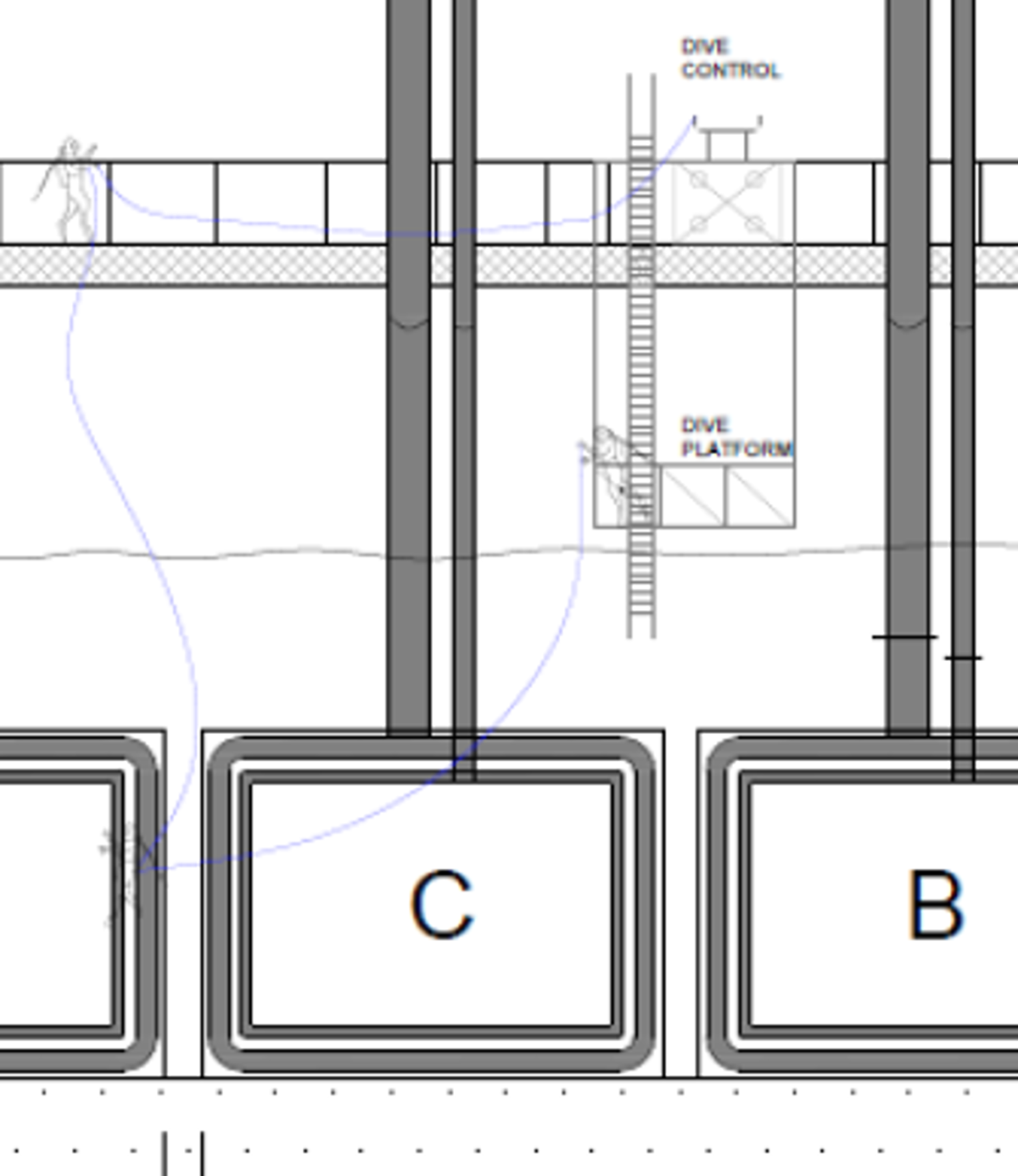

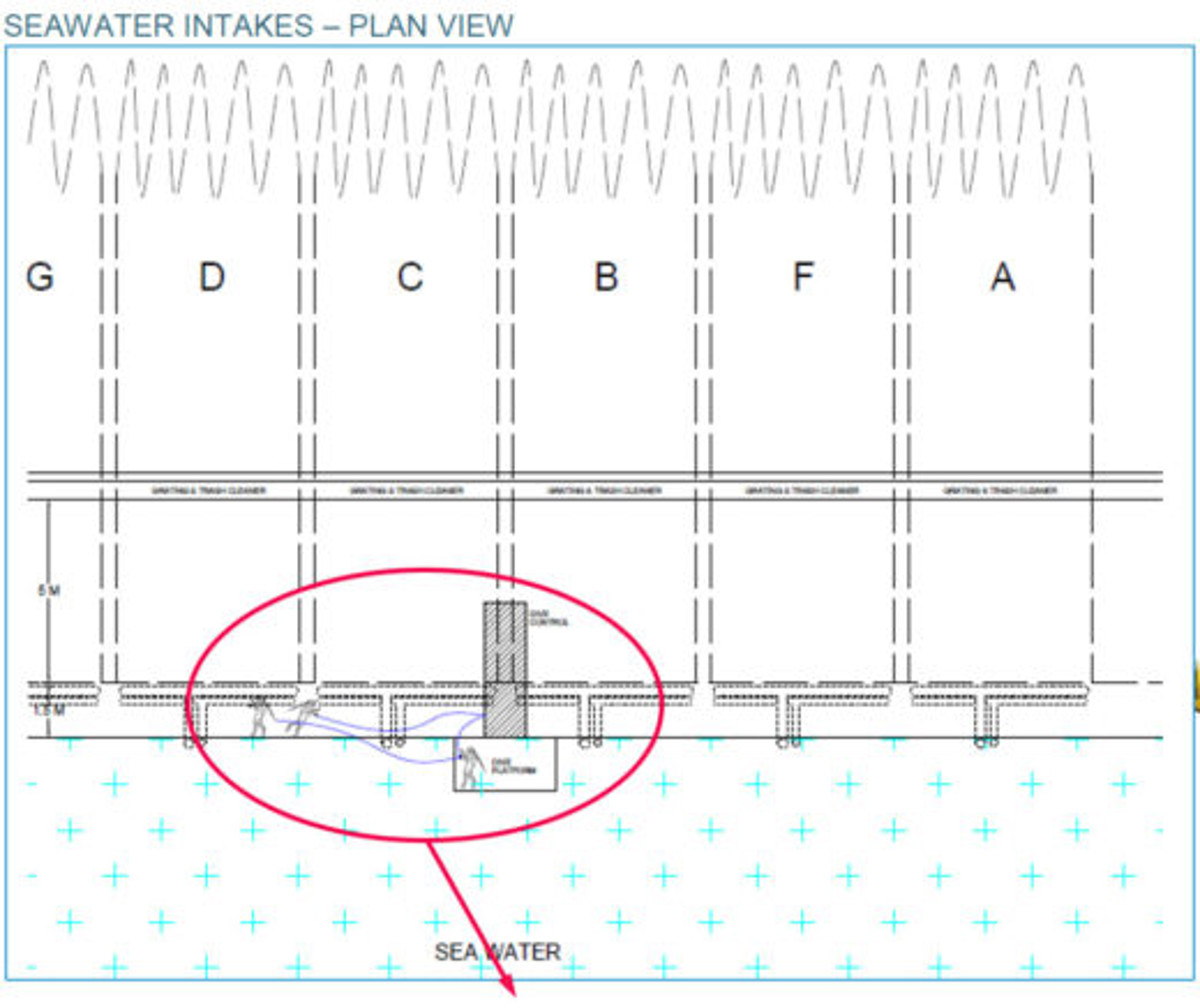

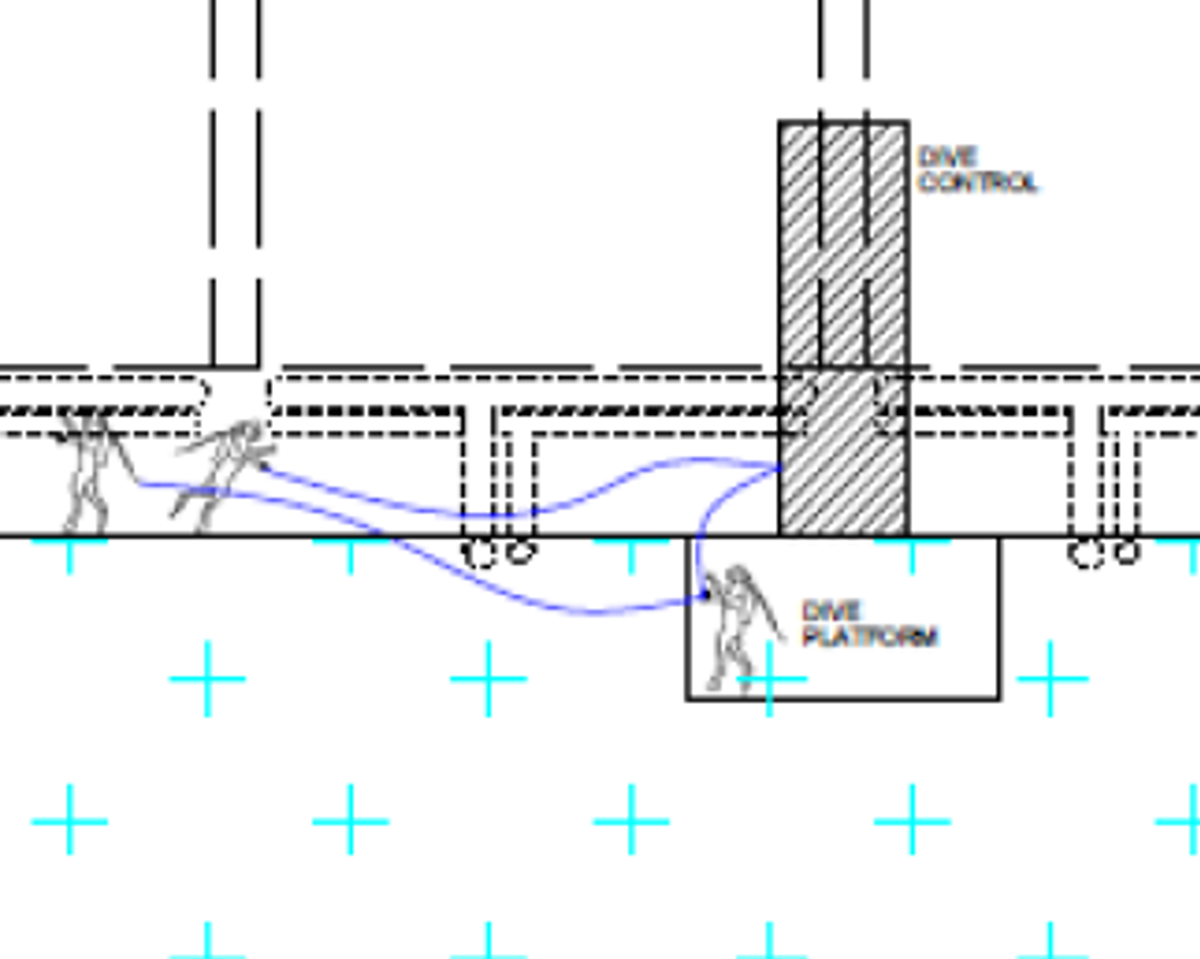

The incident occurred when two divers were working on some underwater clamps associated with two chlorination dosing lines on either side of the entrance to a gravity fed seawater intake located in a culvert.

Each of a number of culverts at the location contained a seawater intake fitted with an automated grating and trash cleaning system recessed 5m from the main opening. The diving operation necessitated moving repeatedly back and forth across the 5m wide intake opening between the clamps. This allowed some slack to be unintentionally introduced into the divers deployed umbilical.

After an extended period of incident free operations, one of the divers’ umbilicals became entrapped with the automated trash cleaning system, resulting in the diver being pulled towards the intake. The 2nd diver cut the umbilical to facilitate escape and both divers ascended to the surface in a controlled manner without injury.

Findings

Our member’s investigation revealed the following:

- The presence of an automated trash removal system was not communicated by the asset owners to the project team.

- As a consequence of this omission there was no system in place to ensure the automated trash removal system was effectively isolated.

- There was a “lock out/tag out” system in place for the seawater intake valves.

- The project risk assessment was not effectively reviewed on site to identify appropriate controls for site-specific hazards.

- The position of the dive tender was not relocated as the dive progressed across the face of the multiple intakes, meaning that excess umbilical was deployed in the water, increasing the potential for snagging.

Recommendations and Corrective Actions

Our member identified the following recommendations and corrective actions:

- Improvements were made to the project start up process to ensure that critical information related to automated systems is properly passed on.

- Physical barriers to be placed across the intakes.

- Lock out/tag out confirmation of the automated systems to be verified before resuming diving activities.

- This is captured in the Pre-dive checklist.

- Project manager to verify and confirm that the activity risk assessment has been reviewed on site by the team before resuming operations.

- Dive tender to be repositioned throughout the diving operations to ensure that the optimum amount of deployed umbilical is in the water column to minimise the likelihood of snagging.

Notes

IMCA notes that this was actually a differential pressure incident where the diver’s line was drawn into the gravity fed seawater intake by the suction generated. This is an excellent example of the very serious (and often potentially fatal) risks faced by divers in differential pressure situations. In this case, the important point is that the pressure differential was not identified. Differential pressure situations are subtle and difficult to spot, widespread, and potentially deadly to divers. Vigilance is key to the prevention of such incidents.

The following information will also be of use and interest:

- Association of Diving Contractors International (ADCI) video on the dangers of differential pressure

- UK Health & Safety Executive (UKHSE) Diving Information Sheet No. 13: Differential pressure hazards in diving

- UKHSE research report RR761: Differential pressure hazards in diving.

Featured Safety Flashes

-

IMCA SF 06/14

16 April 2014

-

IMCA SF 14/11

23 December 2011

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.