Uncontrolled ascent – loss of lift bag to surface

- Safety Flash

- Published on 28 May 2010

- Generated on 29 April 2025

- IMCA SF 03/10

- 3 minute read

Jump to:

A Member has reported the loss of a lift bag to surface.

What happened?

During a surface-supplied diving operation from a dynamically positioned diving support vessel (DP DSV) in approximately 24 metres of seawater, a 10 tonne parachute lift bag had been attached to a pipeline as an installation aid in accordance with the member’s procedures as part of a sleeper rectification program. At the previous site a successful/uneventful installation had been accomplished only a few hours earlier using 2 x 5 tonne and 2 x 10 tonne lift bags.

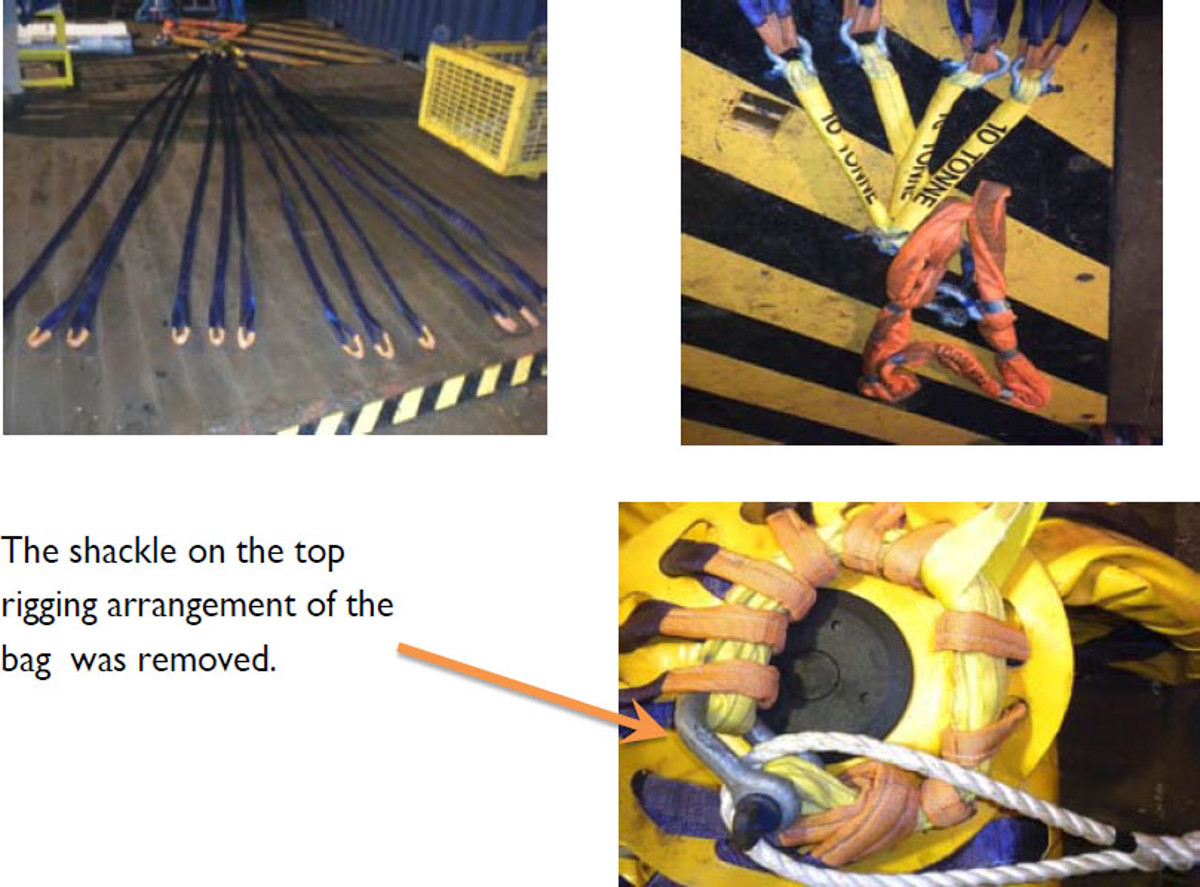

The bag had been partially inflated in order to obtain a vertical position and volume sufficient to allow an inspection prior to any additional inflation. At this point the diver observed and reported a shift of the bag upwards relative to the rigging strops secured to the pipe. Shortly thereafter, the bag slipped away from its rigging and ascended to surface.

- The diver reported the loss of control immediately and the bridge was notified

- The main rigging and inverter line remained attached to the pipeline

- It was determined that the shackle joining the top end ‘cradle ring strap’ had mistakenly been removed 4 hours earlier when the bag had been retrieved to deck from the previous deployment.

The member reported that no injuries had been sustained and the lift bag had been damaged, but the diver could have potentially experienced an embolism or have been fatally injured if he had been dragged to the surface.

The Member noted the following root causes:

- A lack of awareness on the part of the rigger who had de-rigged the bag.

- A detailed pre-deployment inspection regime had not been in place.

- The cradle-ring-strap and single pin shackle arrangement at the top of the bag had ‘routine’ly been used as a common securing point for both the main rigging and the inverter line which represented a single point failure.

- The single pin shackle had been easily removed by hand as it did not require a tool, nor did it have any distinguishing markings (e.g. paint) to indicate that it formed an integral component part of the cradle-ring-strap configuration.

All rigging attached to the lift bag was recovered with no damage or distortion found. The shackle on the top rigging arrangement of the bag was removed.

Rectification taken and recommendations made by the member company:

- Activities were ceased and an investigation carried out which included two onshore managers.

- The model of bag used was quarantined until further notice.

- A pre-deployment model specific check list was produced for a similar model lift bag which utilised a continuous loop cradle sling.

- A ‘stand down’ was held and personnel involved in all phases of lift bag usage, including the handling and deployment, were familiarised with the safety critical elements and specifics of the equipment.

- Black Box footage of the event was to be developed into a training aid and lessons learnt material.

- Communicate to vendors the issue of an inherent single point failure.

- Communicate to the vendors the need for manufacturer and model specific check lists and this was to be included as a future requirement in the member’s purchase procedures. The member noted that the manufacturer supplied checklist with the bag was a generic check list found in industry guidance documents.

- Review and update the company work instruction for the use of lift bags and include lessons from this incident and any relevant improvements forthcoming by the vendors.

Members may wish to review Guidance on open parachute type underwater air lift bags

Related safety flashes

-

IMCA SF 15/08

9 October 2008

-

IMCA SF 02/08

4 February 2008

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.