Confined space entry hot work fatality

- Safety Flash

- Published on 6 February 2025

- Generated on 6 March 2026

- IMCA SF 02/25

- 2 minute read

Jump to:

Late last year an incident was brought to IMCA’s attention relating to a confined space entry hot work fatality in a shipyard.

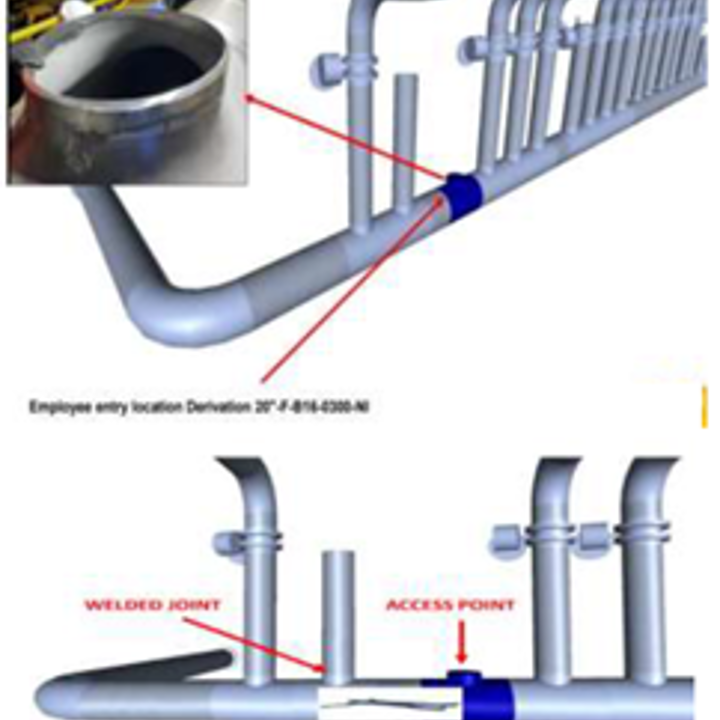

A welder entered a 86cm (34”) pipe through a 50cm (20”) opening to check on welding being carried out. He was found unconscious by another worker who had noticed his absence, and called the emergency team. First aid was provided by the shipyard rescue teams and he was then taken to a local hospital, where, though care was continued, he was pronounced dead.

Confined space

Diagram of confined space

What went wrong?

The report seen by IMCA identifies the following issues:

- Poor Communications – there was no signage at the pipe warning of a confined space or prohibiting entry.

- Physical entry into the confined space was not blocked.

- There was a failure of leadership – inadequate supervision.

- There was a failure in planning and risk assessment – whilst the Permit to Work was comprehensive for all welding activities at the site, it did not address or warn about the specific risk of inert gas (argon) related to the task being performed.

- Motivation: there was a lack of clarity in the criteria for evaluating welders' performance, which generated doubts about possible consequences due to failed welding. In addition, though the welders had been told not to enter the pipe, they were not fully made aware as to why this was: conditions inside the pipe were not known by the welders.

- Procedures were inadequate: the welding procedure did not clearly address the welders' performance criteria, nor did it address the specific risks associated with the use of inert gas.

Actions taken

- Installed physical barriers at all temporary pipe openings with diameters equal to or greater than 40cm (16”), with signage prohibiting entry into the pipe.

- Amended procedure for restricted space requirements for pipes with a diameter equal to or greater than 40cm (16”).

- Provided specific additional input to risk assessment and Permit to Work for activities involving inert gases.

- Ensured better communication to welders of the criteria impacting the evaluation of their performance, and reiterated awareness of the Life-Saving Rules and safety with regard to confined space entry.

Members may wish to refer to:

· Fatality during confined space entry (IOGP)

Related Safety Flashes

-

IMCA SF 04/24

19 February 2024

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.