Umbilical management – near miss

- Safety Flash

- Published on 11 January 2023

- Generated on 3 March 2026

- IMCA SF 02/23

- 2 minute read

Jump to:

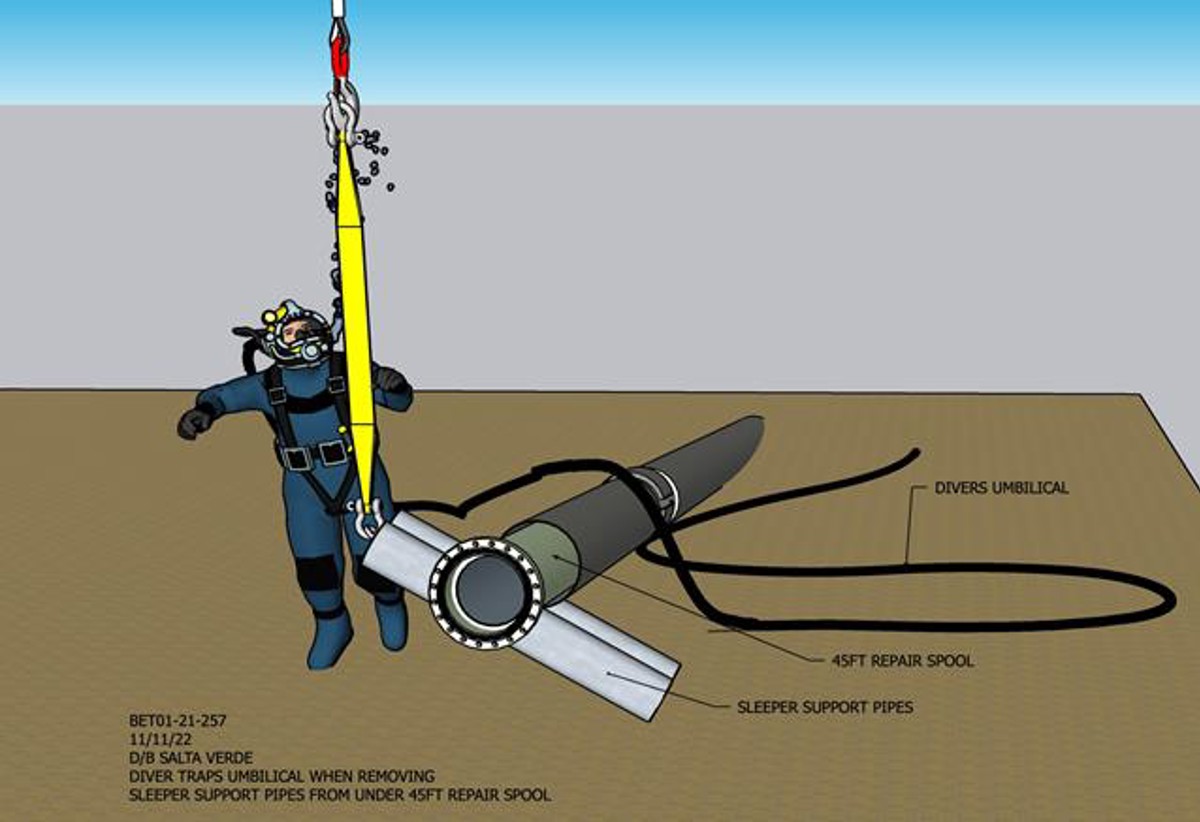

A diver was working with the barge crane to remove two sleepers from under a newly installed 16” x 45 ft (40cm x 13.5m) repair spool.

What happened?

The crane was rigged directly onto the sleepers to be moved. Once the sleepers cleared, the pipeline moved and rolled over a section of the divers umbilical. The diver discovered that his umbilical was trapped and was able to free it himself. Visibility was excellent, it was daylight, and the diver was able to move his umbilical over to a suspended section of pipe, and was unharmed.

Figure 1: Driver trapped the umbilical when removing sleeper support pipes from under 45ft repair spool

What went right?

- Both diver and supervisor were very experienced and were able to work very quickly on a solution.

- This was a decompression dive that did not exceed the planned bottom time.

What were the causes?

- Procedural – no procedure existed for the sleeper removal, due to an oversight during the project planning phase.

- Human Performance – the diver did not recognise the line of fire umbilical management hazard.

- Human Performance – the Dive supervisor did not call an “all stop”, due to a lack of full procedural understanding. No management of change (MoC ) was created.

Actions

- Develop a removal procedure to include the removal of the diver’s umbilical from the bottom, before starting the operation.

- Review with the entire crew the Umbilical Management process and sleeper removal procedure.

Related Safety Flashes

-

IMCA SF 03/22

28 January 2022

-

IMCA SF 29/21

28 October 2021

-

IMCA SF 09/17

3 May 2017

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.