Failure of life raft securing strap

- Safety Flash

- Published on 10 January 2020

- Generated on 9 January 2026

- IMCA SF 02/20

- 2 minute read

Jump to:

A life raft from the starboard forward life raft station made an unplanned deployment into the sea

What happened?

The incident occurred in early afternoon with calm seas and clear skies.

The life raft remained attached to the painter line and vessel.

The vessel was later able to safely recover the life raft to deck.

What went wrong?

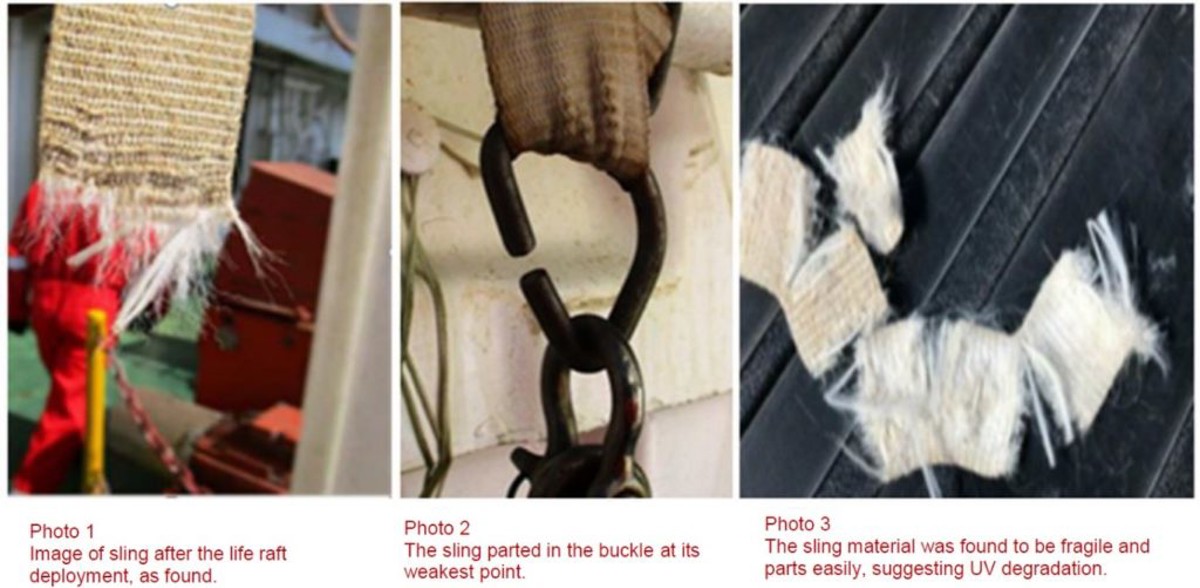

There was a failure of the securing straps designed to hold the life raft in place. This allowed one life raft to deploy into the sea. The securing straps had only been installed one-year prior to failure.

The vessel was in operation in the Middle East, with high temperatures and high UV levels.

What was the cause?

The hold back strap, used to retain the life raft in place, was found to be degraded to the point of failure.

This appears to have been caused due to the extremes of temperature and ultraviolet light.

Action

Inspection routines for life rafts and associated lashings should consider the environmental conditions, and all parts of the equipment should be visually inspected and maintained at appropriate intervals.

Assumptions should not be based on vessel operating areas; UV damage may occur within any region.

- Conduct immediate inspections of life raft securing straps and associated equipment.

- Replace any items which are of concern or appear to be faulty.

- Verify manufacturer’s instructions with regards to the service life of the securing straps.

- Any temporary secondary securing arrangements should not affect the ability to launch any life raft – as per SOLAS requirements.

Members may wish to refer to UK MCA Guidance note MGN 343 Hydrostatic release units: stowage and arrangements for liferafts.

Related Safety Flashes

-

IMCA SF 21/18

17 September 2018

-

-

IMCA SF 21/18

17 September 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.