Crew member fainted after working in water ballast tank

- Safety Flash

- Published on 10 January 2020

- Generated on 25 April 2025

- IMCA SF 02/20

- 3 minute read

Jump to:

A crew member felt faint and subsequently collapsed after working in a confined space

What happened?

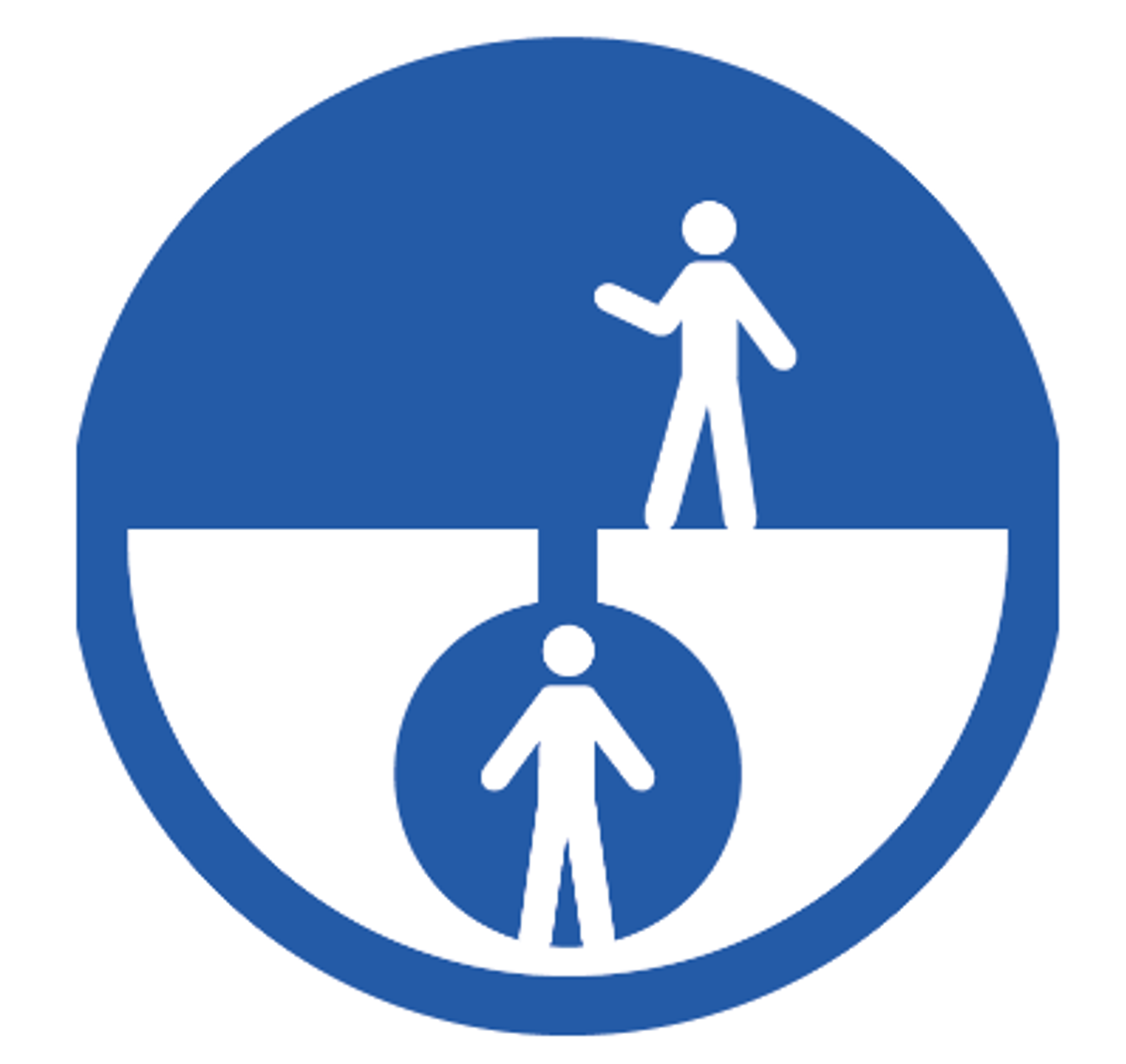

A crew member felt faint and subsequently collapsed after working in a confined space. The incident occurred following the work of a four-person team on rust removal maintenance of the water ballast tanks.

The team spent the day removing bottom sediments and rust scales in a tank and came out in the late afternoon for dinner. One crew member stated that he felt dizzy and was experiencing a headache and blurred vision.

The team assumed dehydration was the cause and proceeded to return to their cabins in preparation for dinner. During the elevator ride to the upper deck, the crew member fainted.

The team contacted the Master and Chief Officer who administered medical oxygen before transferring the crew member to the ship’s hospital for further observation. After regaining consciousness, the crew member reported that he had smelled a strong odour after dislodging a large caked piece of sediment from the bell mouth.

Following medical advice, the crew member was treated for suspected hydrogen sulphide poisoning as a worst-case scenario. The crew member recovered quickly and returned to full duties two days after the event.

Our member noted that their company ‘Enclosed Space Entry’ procedures were all followed, and all safety measures implemented as per the risk assessment and permit to work (PTW). The tank had been open and continuously ventilated for the three days prior to the incident occurring, and all personnel were wearing portable multi-gas detectors and oxygen monitors.

What were the causes?

- Immediate causes:

- Enclosed space atmospheres are hazardous as a result of a combination of potential conditions even after full ventilation and atmosphere testing has been completed.

- Physical discomfort caused by lack of airflow, warmer temperatures, awkward positioning, slippery surfaces and lack of illumination can lead to personnel feeling unwell, dehydrated and fatigued.

- Ballast tanks can contain toxic gases – hydrogen sulphide can be found in tank sediment as a result of decomposing sea life which may enter the tank.

- Causal factor – lack of knowledge; the tank team were not fully aware of the hazards associated with the task and the crew member did not recognise the potential danger when he smelled the strange odour.

- Root cause – the risk assessment did not adequately address the hazards and severity of the task.

Action

Immediate action taken was all maintenance work in the water ballast tank was halted until the atmosphere was confirmed as safe for entry.

The Chief Officer entered the tank in SCBA and conducted repeated tests after deliberately agitating the tank sediment.

However, no evidence of hydrogen sulphide or any other harmful gases were noted.

Subsequently:

- Review the risk assessment for enclosed space entry and ensure that the hazards identified are specific to the tank/spaces being entered.

- Ensure effective toolbox talks (TBT) are carried out; discuss the hazards identified in the risk assessment and ensure the team fully understands the need to take regular breaks, the importance of staying hydrated and what to do in an emergency or if the tank atmosphere is compromised.

- Ensure the team on-board are aware of the potential gases which could be found in such tanks and how they behave and can be recognised. Hydrogen sulphide is heavier than air so tends to collect at the tank bottom as a colourless gas that at low concentrations smells like rotten eggs.

- At higher concentrations it will deaden the sense of smell – and the person!

Related Safety Flashes

-

IMCA SF 14/19

18 June 2019

-

-

IMCA SF 01/19

28 January 2019

-

-

IMCA SF 01/19

28 January 2019

-

-

IMCA SF 22/15

15 December 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.