LTI: Finger injury during work with rotating machinery

- Safety Flash

- Published on 13 February 2019

- Generated on 3 March 2026

- IMCA SF 02/19

- 2 minute read

Jump to:

An electrician tried to modify a cable shoe using a pillar drill in the engine room workshop.

What happened?

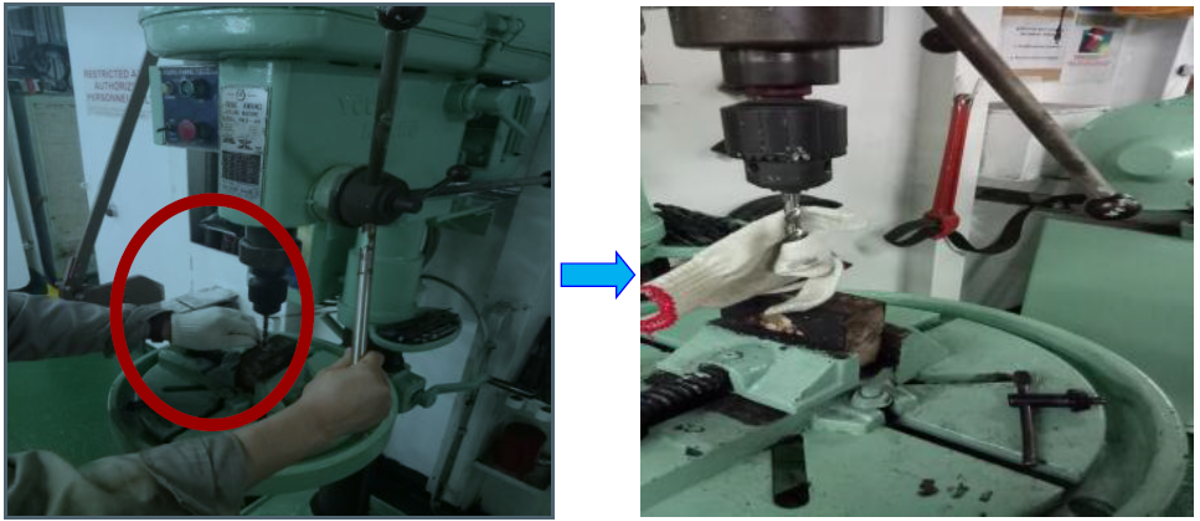

During initial use of the drilling machine, the electrician secured the cable shoe with a vice and did not wear any gloves. However, during subsequent drilling to finalise/enlarge the hole, he did not secure the cable shoe properly, and he held it with his left hand whilst wearing cotton gloves, as the cable shoe had become too hot to touch.

His glove got entangled with the drill bit, resulting in a serious injury to his left index finger. Following first aid, he was medevaced by helicopter and transferred to hospital for further treatment. Medical examination revealed a partial amputation of his left index finger and open fracture dislocation of his thumb and damaged tendons, requiring surgery.

The injured person was not tired and was working appropriate hours at the time of the incident.

What went wrong? What were the causes?

- There was no evidence of any risk assessment, and a toolbox talk (TBT) was not conducted.

- The electrician was wearing gloves while using the drilling machine, though there was a warning sign prohibiting wearing of gloves while operating the drill posted nearby.

- Immediate causes:

- Improper use of personal protective equipment (PPE): glove got entangled with the drill bit.

- Carelessness: warning signage was ignored, and the cable shoe was not secured properly before drilling started.

- Improper use of personal protective equipment (PPE): glove got entangled with the drill bit.

- Causal factors:

- Inadequate planning and lack of risk assessment.

- The electrician did not inform others of his intent to use the drill, and he was rushing to finish the work.

- Inadequate planning and lack of risk assessment.

What lessons were learned?

- Gloves and loose clothing should not be worn when working with rotating machinery.

- “More haste – less speed” – avoid shortcuts and rushing to finish the job.

- Members can refer to IMCA’s short video Watch your hands from the Be prepared to work safely safety promotion materials.

Related Safety Flashes

-

IMCA SF 28/17

7 November 2017

-

-

IMCA SF 19/17

2 August 2017

-

IMCA SF 04/15

20 March 2015

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.