Hose fire caused by flashback in oxygen and acetylene hoses

- Safety Flash

- Published on 20 February 2014

- Generated on 11 April 2025

- IMCA SF 02/14

- 4 minute read

Jump to:

A Member has reported an incident in which a sub-contractor’s oxygen and acetylene cutting hose burst and caught fire.

What happened?

The incident occurred when the welder was ready to ignite the cutting torch head. The acetylene valve on the quad was slowly opened; the welder then opened up the oxygen and acetylene valves on the cutting head and ignited the tip. Instantly, there was a bang and flames were seen coming from a coil of oxygen and acetylene hoses on the deck. The burst created sufficient ignition and force to cause the hose to split in three separate places. The splits were located at the in-line hose connection points. The fire was immediately extinguished by the fire watcher who was able to fold over the two hoses thus preventing further gas flow. The gas supply was isolated at the cylinder and the hoses were vented. There were no injuries.

Our Member's investigation noted the following:

- The primary safety condition breached in this incident was: always use the correct tool safely to carry out the job.

- Following the incident an inspection of the hoses revealed brittle and perished sections along the whole hose.

- It was suspected that the non-return valve on the cutting torch was inoperative, allowing a ‘flashback’ to take place within the hoses.

- Pre-use checks by the welders revealed that they set up the equipment without leak checking connections prior to using the equipment.

- The sub-contractor had a suitable leak detection substance but none was available at the incident site, and therefore the leak testing of cylinders and connectors had not been carried out.

Our Member drew the following lessons:

- Use a proprietary leak detecting spray or solution suitable for use with oxy/fuel systems, to check all fittings prior to use. Soapy water or solutions containing grease or oils should NOT be used on oxygen systems.

- Leaking or damaged components should be replaced immediately.

- Leaking hoses should not be repaired, but should be shortened to remove damaged sections. The shortening and refitting should be conducted using appropriate and correct tools and equipment designed for that task. Screw tightened crimps (‘jubilee clips’) should not be used, as their use increases the risk of leaks due to the potential for over/under-tightening.

- All welding and cutting equipment should be inspected prior to use, including:

- Condition of hoses any perished hoses should be replaced immediately

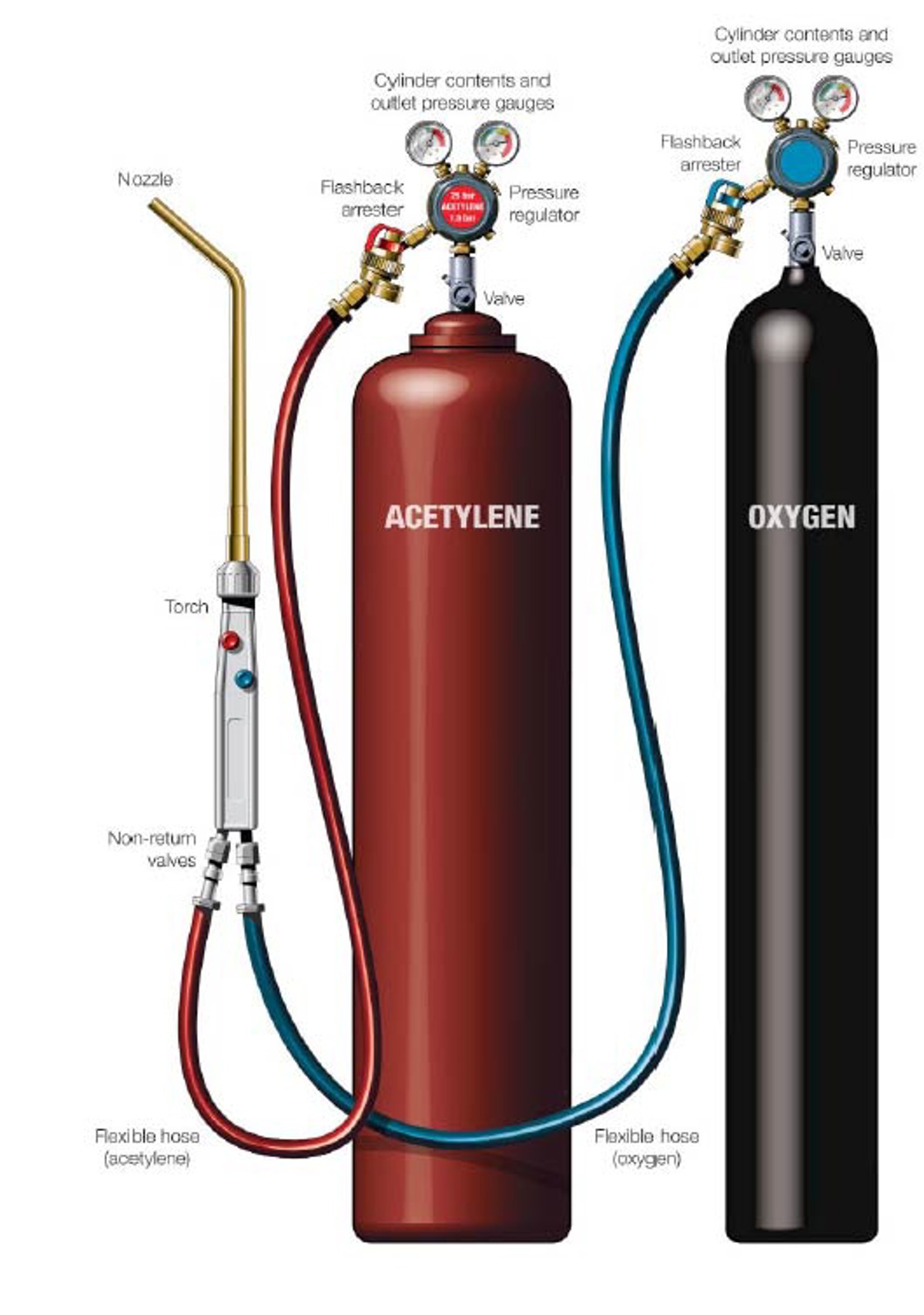

- Flashback arrestors are fitted at both gauges

- Non return valves or flashback arrestors fitted at torch side

- Correct hose crimps are used at all fittings

- Leak tested

- Gauges are serviceable

- All fittings are free from oil and grease contaminants

- Ensure thread tape is not used on any connections

- Bottle key in place on acetylene cylinder

- Cylinders securely stored upright

- Bulk gas storage has a minimum separation of 3 meters.

Correct set-up of oxygen/acetylene equipment

Our Member concluded:

- Flashbacks are commonly caused by a reverse flow of oxygen into the fuel gas hose (or fuel into the oxygen hose), producing an explosive mixture within the hose. The flame can then burn back through the torch, into the hose and may even reach the regulator and the cylinder. Flashbacks can result in damage or destruction of equipment, and could even cause the cylinder to explode. The following precautions will help to prevent flashbacks:

- Use the correct lighting-up procedure. Purge the hoses before lighting the torch to remove any potentially explosive gas mixtures. Use a spark igniter and light the gas quickly after turning it on

- Ensure the cutting torch is fitted with spring-loaded non-return valves

- Use the correct gas pressures and nozzle size for the job

- Maintain the equipment in good condition;

- These measures will reduce the risk of a flashback but will not completely eliminate it. Non-return valves will not stop a flashback once it has occurred. Protecting cylinders from flashbacks:

- Fit flashback arresters to both the oxygen and fuel gas hoses near to the regulators. For long lengths of hose, fit arresters on both the torch and the regulator

- The fitting of a flashback arrester is not a substitute for safe working practice. After a flashback, carefully check for damage to the torch, hoses, regulators, flashback arresters and other components. Replace parts if needed.

Related safety flashes

-

IMCA SF 08/13

21 May 2013

-

IMCA SF 07/12

10 July 2012

-

IMCA SF 08/09

19 June 2009

-

IMCA SF 09/08

21 May 2008

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.