Divers lifted off seabed by Clump Weight

- Safety Flash

- Published on 9 January 2024

- Generated on 2 March 2026

- IMCA SF 01/24

- 2 minute read

Jump to:

Rapid change in depth had the potential to cause pressure induced injuries.

What happened?

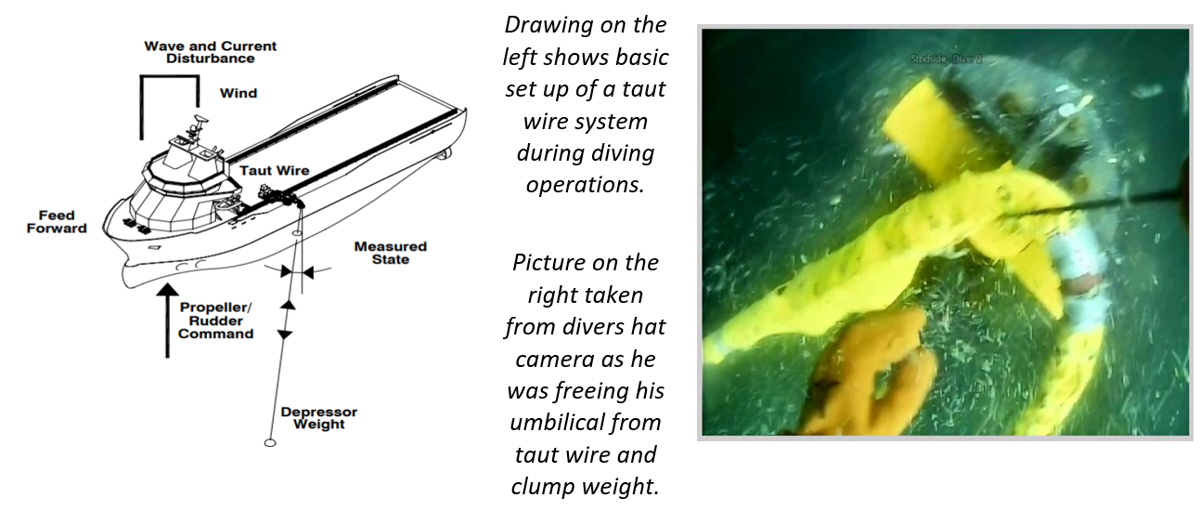

Whilst the Diving Support Vessel was conducting subsea diving operations, the bridge team recovered the taught wire pulling the divers from the seabed to 18m above the diver’s maximum excursion depth. This rapid change in depth had the potential to

cause pressure induced injuries or injuries with direct contact with the taut wire clump weight. Thankfully, in this instance, both divers reported well post-transfer and following subsequent tests.

What went wrong?

- Open comms system was installed but silenced and set to ‘closed circuit’ – delaying the bridge team’s reaction to the lifting of the divers.

- The bridge team made the incorrect assumption that Dive Supervisor was aware of the taut wire recovery – it was recovered without final repeat back and approval by Dive Supervisor.

- It had become customary practice to recover taut wires when divers were ‘seen’ as being in a ‘Position of Safety’ and not with verbal confirmation from the divers that this was so.

- There was a gap in the management system, taut wire ‘weight’ lifting operations were not covered by a lift plan.

Lessons and actions

- Internal company diving information notice issued, including requirement that “divers return under bell and clear umbilicals prior to any deployment or recovery of taut wires”.

- Lift plans for taut wire deployment / recovery now include step to ‘confirm divers are in a place of safety’ before start of operations.

- Ensure sufficient diver awareness on umbilical management to prevent entanglement.

- Operational communications instruction issued to all company vessels involved in diving operations:

- Ensure communication is in clear and concise language to avoid any potential for misinterpretation.

- Ensure commands and/or instructions are repeated back prior to carrying them out, to verify understanding.

- If communication is not clear or there are any doubts on the command issued, an ALL STOP should be called.

Related Safety Flashes

-

IMCA SF 18/19

25 July 2019

-

-

IMCA SF 08/18

11 April 2018

-

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.