Confined space entry: Person overcome by fumes and rendered unconscious

- Safety Flash

- Published on 28 January 2019

- Generated on 10 February 2026

- IMCA SF 01/19

- 2 minute read

Jump to:

Three crew members on a vessel were tasked with opening a sewage tank inspection hatch to check the condition of a faulty sensor.

What happened?

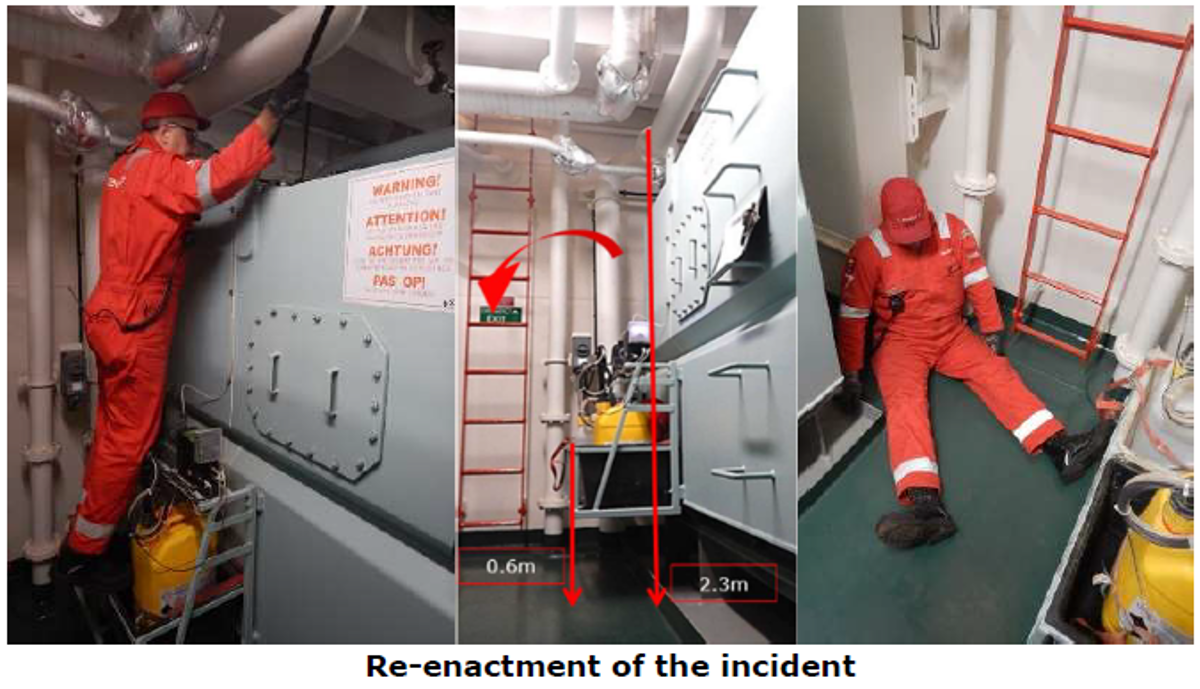

The hatch was subsequently removed to facilitate cleaning of the sensor, with one individual standing on a fixed rack to gain access.

During the task, that individual was overcome by a concentrated plume of Hydrogen Sulphide (H2S) from the tank, causing him to become unconscious and fall to the deck.

He was unconscious for around 90 seconds and suffered minor cuts and bruises to his right hand.

What went wrong?

Safe systems of work were not followed:

- There was a failure to identify potential hazardous gases as part of the risk assessment.

- There was non-adherence to the permit to work (PTW) procedure.

- There were inadequate working at height controls.

- There was an inadequate tool box talk.

The manufacturer’s instructions for opening the inspection tank were not followed. In particular, there was no check for potentially hazardous gases.

The sewage treatment plant had not been operated and maintained in line with manufacturer’s instructions, which led to the build-up of Hydrogen Sulphide.

Actions

- Ensure safe systems of work are followed for all maintenance activities including adherence to the PTW, task risk assessment, toolbox talk (TBT), working at height and associated procedures where applicable.

- Before using or maintaining equipment, ensure that all relevant personnel are familiar with the operation, required maintenance activities, associated risks and required safety controls as defined by the manufacturer’s instructions.

- Ensure that workers tasked with the operation and maintenance of sewage treatment plant are made aware of the potential for H2S, the risks associated, the required control measures including the requirement for breathing apparatus if there is potential for H2S release.

- Re-iterate to all workers that they have a responsibility to stop the job if during the work:

- circumstances change and present new additional risks

- they feel uncomfortable or unsafe or are unsure of the planned task.

- circumstances change and present new additional risks

Related Safety Flashes

-

IMCA SF 22/15

15 December 2015

-

IMCA SF 03/14

13 March 2014

-

IMCA SF 01/12

25 January 2012

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.