The cascade effect

- DP Event

- Published on 3 April 2024

- Generated on 5 January 2026

- DPE 01/24

- 3 minute read

Incident

Jump to:

A critical incident aboard a DP vessel, five years post-construction, which experienced a significant power management failure.

The incident unfolded during what was considered ‘routine’ maintenance in the engine room and led to a series of cascading failures impacting the vessel’s power supply and propulsion control.

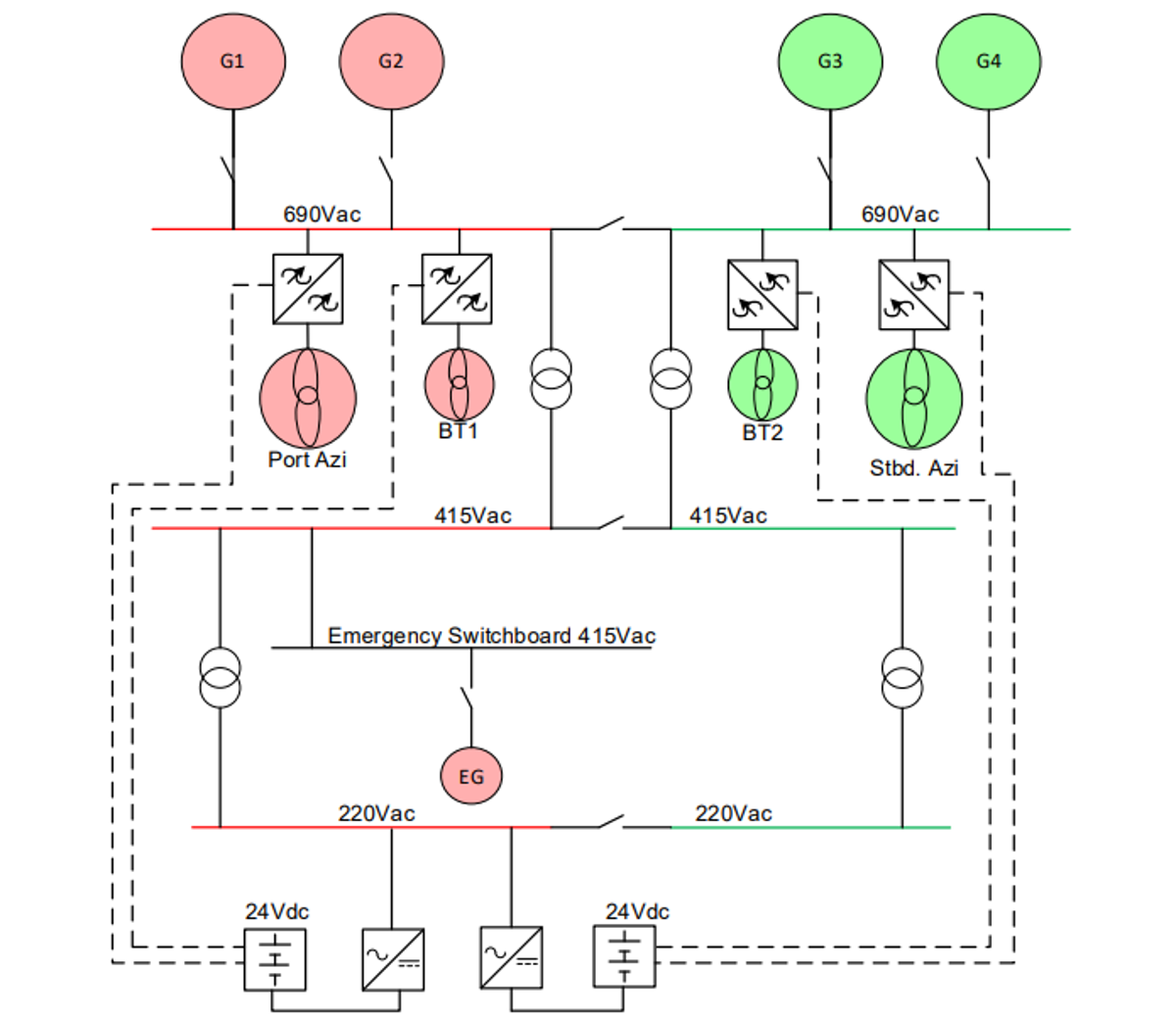

Figure – Overview of power system:

What happened?

The incident initiated when the engine room watchkeeper attempted to replace the left filter of the duplex fuel oil filter of Diesel Generator (DG) No. 1. This generator, integral to the port redundant system, was responsible for powering the 415v and 220v bus A and the emergency switchboards.

1) Failure of DG No.1: Following the filter change, DG No. 1 experienced a blackout due to fuel oil starvation, attributable to incorrect operation of the duplex fuel filter.

2) Inadequate Power Supply from DG No.2: DG No.2, also part of the port redundant group, was initiated but failed to supply power to the bus.

3) Emergency Generator Disconnection: The emergency generator did not engage with the emergency switchboard as the breaker was inadvertently left in manual mode, resulting in a loss of power to the emergency bus bar.

4) Battery Failure: Control power for DP essential equipment, typically supported by batteries during such failures, was compromised as the batteries were drained.

5) Design Flaw in Power Distribution: Despite no failure in the starboard redundant group, the loss of all propulsion control power occurred due to a design fault. The 220v AC and 24v DC systems, providing control power for all propulsion, were sourced solely from the port redundant group.

This design flaw was not identified in the Failure Modes and Effects Analysis (FMEA) or during the annual DP trials, the most recent of which was conducted less than three weeks prior to the incident.

Conclusion

This incident underscores the importance of thorough initial FMEAs, tracking modifications, and ensuring up-to-date documentation. It highlights the need for frequent testing of redundancy groups, implementation of a robust permit-to-work system, and the use of precise DP checklists in both engine room and bridge operations. The event serves as a critical reminder of the intricacies and potential vulnerabilities in power management systems on DP vessels, emphasising the need for diligent maintenance, rigorous testing, and proactive design reviews to ensure operational safety and reliability.

This incident underscores the critical importance of precise control and monitoring of DP system modes during sensitive offshore operations. The swift action by the DPO mitigated the potential risks associated with the unintended mode change. The subsequent software modification and procedural reviews enhance the safety and reliability of DP operations, emphasising the need for continuous vigilance and robust system controls in dynamic maritime environments. It also highlights the importance of robust procedures around field entry and activity specific guidelines.

Actions

In response to this incident, several corrective measures were undertaken:

- Prohibition of maintenance on active or passive DP components within 500 metres of an installation to be indicated in the Engine Room DP checklist and handover checklist.

- Permanent modification of the switchboard setup to ensure propulsion control power is

supplied from different redundant groups. - Verification of switchboard setup by two separate watchkeepers.

- Regular DP blackout drills.

- Regular training on switchboard setup.

- Enhanced battery checks and testing routines.

- Review and update of the company’s test and trials programmes.

Latest DP incidents

-

Simultaneous Operations

A DP Incident report highlighting the importance of maintaining focus during time on the DP desk

DPE 03/25

18 December 2025

Incident

-

Importance of familiarisation and paying attention

The importance of maintaining full attention during the operator's time on the DP desk can never be underestimated, or forgotten

DPE 03/25

18 December 2025

Incident

-

Worst case failure preparedness

Operators must be prepared for worst case failures

DPE 03/25

18 December 2025

Incident

-

Know your settings

This Dynamic Positioning (DP) incident involved a DP equipment class 2 offshore supply vessel (OSV) during loadout operations from a drilling rig.

DPE 03/25

18 December 2025

Incident

-

DP drill scenario

DP emergency drill scenarios are included to assist DP vessel management and DPOs / Engineers and ETOs to conduct DP drills onboard.

DPE 03/25

18 December 2025

Drill Scenario

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.