Know your vessel capabilities and when to stop!

- DP Event

- Published on 29 July 2024

- Generated on 20 December 2025

- DPE 02/24

- 3 minute read

Incident

Jump to:

An incident that occurred on an equipment class 2 MODU, during well intervention operations.

1. Overview

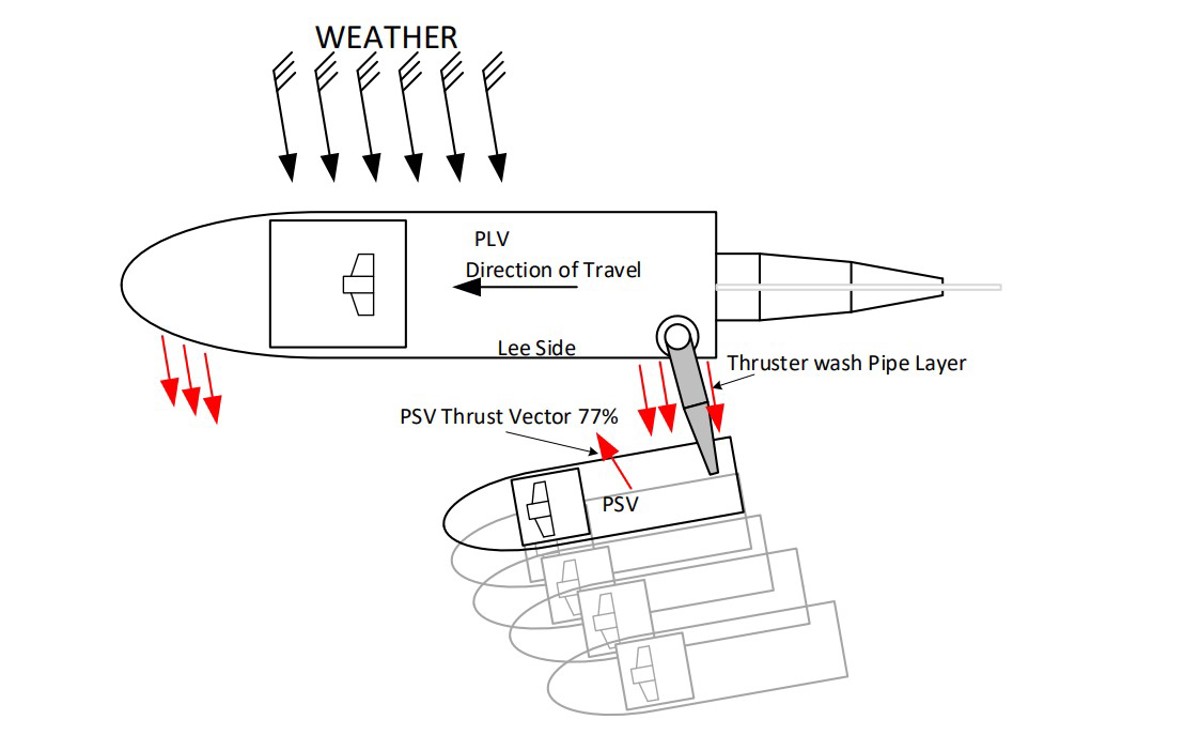

With all engines and thrusters engaged, a DP equipment class 2 pipe supply vessel (PSV) was operating in open bus configuration. The vessel was engaged in cargo operations with a larger DP pipelay vessel (PLV) during adverse weather conditions.

2. What happened?

The supply vessel had been engaged in cargo transfer operations for 25 minutes prior to the DP incident occurring. The weather at the time of the cargo operations was described as adverse with wind gusts of approximately 40knots and a swell of 2m.

Upon arrival alongside the pipelay vessel, on the leeside, the Master of the supply vessel confirmed that they were in position but also made comment that the thrust wash from the pipelay vessel was strong and requested the bridge of the pipelay vessel to reduce the wash in some way. The pipelay Bridge acknowledged the request and cargo operations commenced.

10 minutes later, the supply vessel’s Master informed the pipelay Bridge that they were using too much thrust to stay in position and were up to 70% power capacity with the thrusters at 77% capacity. The pipelay Bridge acknowledged and said they would try to reduce thruster wash.

A further 15 minutes later, the supply vessel suffered a loss of one thruster, and due to the vessel operating outside of the DP equipment class 2 station keeping capabilities, was forced off position by the high thrust wash of the pipelay vessel.

The Master of the supply vessel immediately informed the pipelay vessel Bridge however there was not enough time to disconnect the load on the hook and a container was dragged from the deck of the supply vessel and into the water, as the supply vessel was forced off position. Fortunately, there was no damage to equipment, and no-one was harmed.

3. Findings

Following investigation, the following was found:

- Sudden gusts of wind of around 40 knots created an increased wind load on the pipe layer, causing an increased thruster wash towards the PSV which caused the PSV to lose position.

- The failure of the PSV’s azimuth thruster contributed to the loss of position.

- The operational limits of PSVs operating alongside other vessels were not considered in the Activity Specific Operating Guidelines (ASOG).

- No-one stopped the job: the operation was not stopped despite alarms indicating the PSV was outside defined operational limits.

4. Conclusions

The PSV was clearly operating outside of the vessel’s environmental capabilities and there was no ASOG written for ship to ship cargo operations. The ASOG set out the operational, environmental and equipment performance limits necessary for safe Dynamic Positioning (DP) operations while carrying out a specific activity. Reference: Guidance on operational planning (IMCA M220).

ASOG are used to:

- Ensure the safe and efficient operation of DP vessels.

- Provide a quick reference for DPOs during operations.

- Document the operating parameters for DP vessels.

- Communicate the DP requirements to all stakeholders.

The content of an ASOG will vary depending on the specific activity being carried out, but it will typically include the following information:

- The equipment performance limits that must be met.

- The operational procedures that must be followed.

- The contingency plans that must be in place.

With clear operating procedures in place the Master or DPOs have the confidence to stand up and say “No, stop the job” when their vessel reaches the operating limits.

Latest DP incidents

-

Know your settings

This Dynamic Positioning (DP) incident involved a DP equipment class 2 offshore supply vessel (OSV) during loadout operations from a drilling rig.

DPE 03/25

18 December 2025

Incident

-

Worst case failure preparedness

Operators must be prepared for worst case failures

DPE 03/25

18 December 2025

Incident

-

DP drill scenario

DP emergency drill scenarios are included to assist DP vessel management and DPOs / Engineers and ETOs to conduct DP drills onboard.

DPE 03/25

18 December 2025

Drill Scenario

-

Simultaneous Operations

A DP Incident report highlighting the importance of maintaining focus during time on the DP desk

DPE 03/25

17 December 2025

Incident

-

Importance of familiarisation and paying attention

The importance of maintaining full attention during the operator's time on the DP desk can never be underestimated, or forgotten

DPE 03/25

17 December 2025

Incident

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.