Line of sight

- DP Event

- Published on 5 November 2024

- Generated on 24 December 2025

- DPE 03/24

- 3 minute read

Incident

Jump to:

This case study covers events onboard a DP equipment class 2 vessel whilst holding position in a turbine field, with three position reference systems selected into DP – DGPS, HPR and Fanbeam.

1. Overview

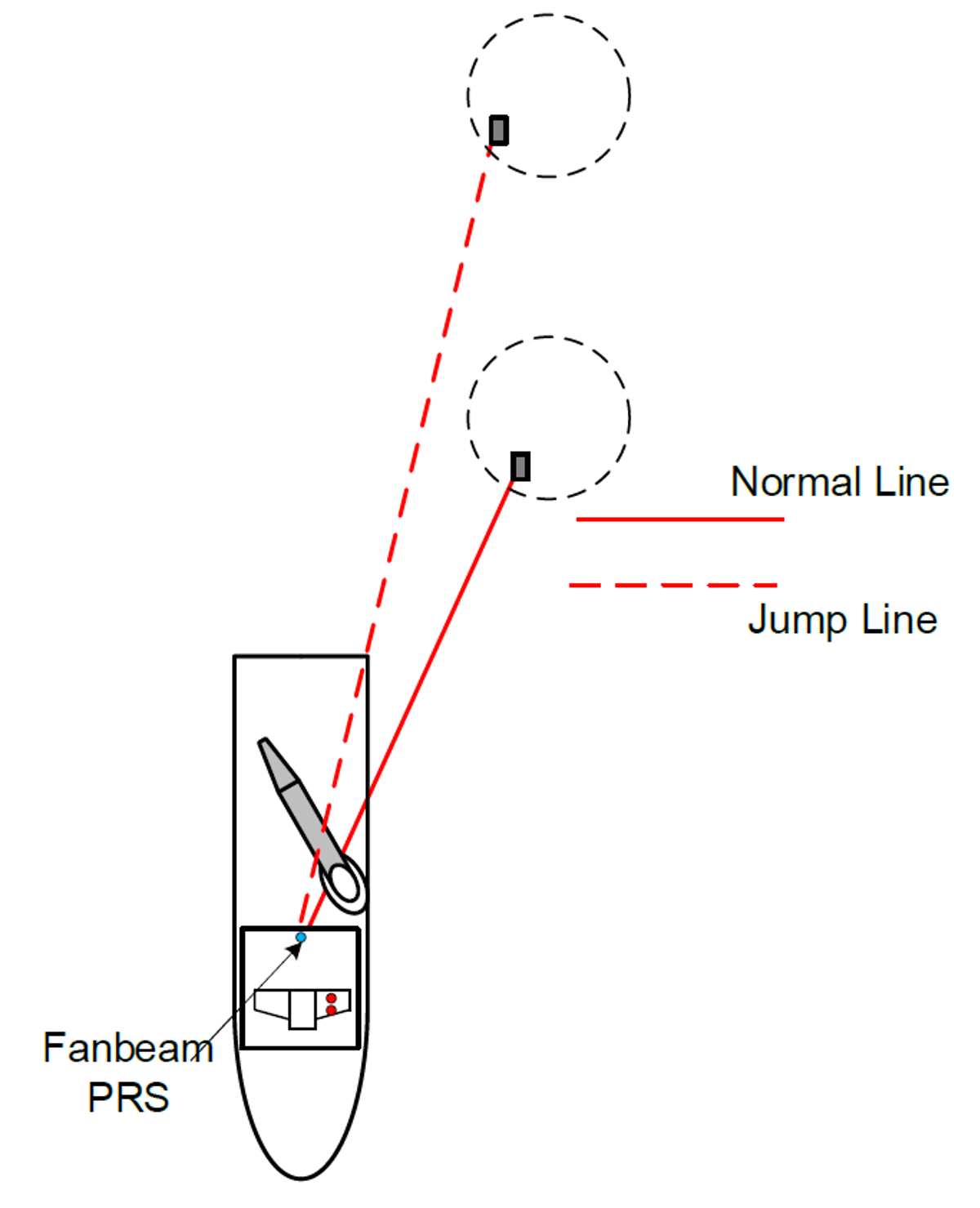

The vessel was holding position when a crane movement blocked the path from the Fanbeam to the reflector on the turbine.

2. What happened?

The DP system registered the drop in reference system, with appropriate alarms and held position on the two remaining reference systems.

However, when the crane moved away from the path of the Fanbeam, the Fanbeam reacquired a connection, and a 4.5m move was experienced.

The SDPO changed over to joystick control and pulled safely out of the field to carry out troubleshooting.

3. Findings

Troubleshooting of the event concluded that:

- Once the path was clear, the Fanbeam reacquired connection with a different reflector, which had a similar range, bearing and signal level as the original reflector.

- As the wrong reflector was acquired, the DP system repositioned the vessel according to the position of the secondary Fanbeam reflector.

- The vessel recreated the scenario, and the same outcome was experienced with each repeat. Without deselecting the Fanbeam from DP, after the signal loss, the Fanbeam reacquired the wrong reflector, and the vessel experienced a position move.

- During an alternative scenario, when the Fanbeam lost connection, the DPOs deselected the Fanbeam from the DP desk. Only when the Fanbeam became available and stable did they reselect the Fanbeam back into DP, and the position remained stable.

- Once the crane covers the line of sight between the Fanbeam and reflector and a prediction error is generated, the DPO should deselect it from DP.

Figure 5 – Fanbeam array

4. Conclusion

Knowing your ship has never been more critical, which is why procedures, training and drills are so necessary.

The issue here wasn’t actually the loss of connection from the PRS, but how the system recovered. Being able to recognise, handle and pre-empt the next steps is imperative to a good outcome, so preparation is key!

The following IMCA Guidance would be relevant to these case studies:

- IMCA M117 – Code of practice for the training and experience of key DP personnel

- IMCA M166 – Code of practice on Failure Modes and Effects Analysis (FMEA)

- IMCA M220 – Guidance on operational planning

- IMCA M247 – Guidance to identify DP system components and their failure modes

- IMCA M252 – Guidance on position reference systems and sensors for DP operations

Latest DP incidents

-

Simultaneous Operations

A DP Incident report highlighting the importance of maintaining focus during time on the DP desk

DPE 03/25

18 December 2025

Incident

-

DP drill scenario

DP emergency drill scenarios are included to assist DP vessel management and DPOs / Engineers and ETOs to conduct DP drills onboard.

DPE 03/25

18 December 2025

Drill Scenario

-

Know your settings

This Dynamic Positioning (DP) incident involved a DP equipment class 2 offshore supply vessel (OSV) during loadout operations from a drilling rig.

DPE 03/25

18 December 2025

Incident

-

Importance of familiarisation and paying attention

The importance of maintaining full attention during the operator's time on the DP desk can never be underestimated, or forgotten

DPE 03/25

18 December 2025

Incident

-

Worst case failure preparedness

Operators must be prepared for worst case failures

DPE 03/25

18 December 2025

Incident

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.