Consequences of decisions – Heading change left too late

- DP Event

- Published on 13 December 2021

- Generated on 30 December 2025

- DPE 04/21

- 4 minute read

Incident

Jump to:

Highlighting the need for good operational planning and a detailed and accurate ASOG/WSOG.

Overview

A DP2 vessel was conducting drilling operations and connected via the riser to the well in 2,000m water depth. The vessel was configured Closed Bus with four out of the six generators connected, six thrusters were selected into DP Control. Along with two DGNSS and one Hydro-acoustic PRS.

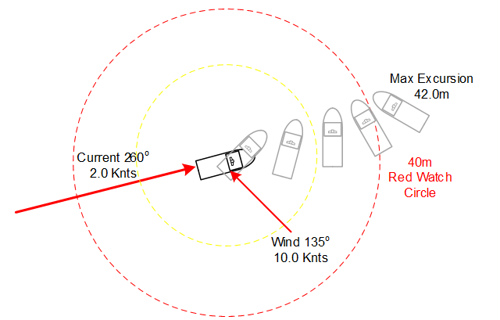

A strong current was running SW to NE at approx. 1.6knts, the vessel was orientated with the stern of the vessel into the oncoming direction of current.

The decision was made to re-orientate the vessel bow into the current which required a heading change of 180o , as per the ASOG this required going to blue (advisory) status, all relevant rig crew were informed and an extra engine was started and connected to the closed bus.

As the heading change was executed, the bow thrusters ramped up to 100% and at 35o into the turn the vessel was already approaching the Yellow watch circle. Gains were adjusted in order to prioritise the heading. When the vessel was abeam of the current, the vessel speed was 0.7knts easterly and increasing, the vessel continued to move off the original position. By 35m off position, the speed of travel was seen to be decreasing. Upon reaching the Red watch circle the speed easterly was at 0.30knts and reducing.

The vessel passed through the Red watch circle and exceeded it by 2m before the vessel started to step back in and return to the original position.

20 minutes from initial heading change the vessel settled on the new heading and position.

Causal factors

Below is a list of causes that together led to the incident highlighted above:

- The decision making process – The parameters around the decision to make the move were not clear from the event report in terms of adherence to ASOG/WSOG, with regards the monitoring of environmental conditions and overall timing of the move.

- The environmental conditions at the time and prior to executing heading change.

- The power of the thrusters were unable to counter the environmental conditions which caused the vessel to breach the red watch circle.

Lessons

The following lessons can be taken from this incident:

- Further risk assessment when undertaking this sort of vessel adjustment is crucial.

- The vessel breached the red watch circle, this is the point where disconnecting was a stated act in the ASOG/WSOG.

- This event highlights the need for good operational planning and a detailed accurate ASOG/WSOG.

Conclusion

This event highlights the need for good operational planning and a detailed accurate ASOG/WSOG. Planning needs to include when DP vessels are operating in an increasing environmental condition or close to the fringes of the vessel’s capability. Considerations should include:

- What are my safe limits for heading or position moves and are these detailed in the ASOG/WSOG?

- What are my limits for safe disconnection (or time to terminate) in the case of being unable to maintain position / heading while also considering post worst case failure capability?

- Key personnel involved in the decision-making process.

- What are my limits for emergency disconnection in the event of loss of position?

- What was the Rate of Turn and acceleration values? This may have contributed to the rapid increase of thrust.

It is not clear from the event report if the decision support tools were available and robust enough to safely execute the heading change undertaken. Likewise, the report makes no reference to capability plots which should show limitations and DP footprint plots which can also provide guidance on the vessel’s maximum operational environment.

Guidelines for the design and operation of dynamically positioned vessels (IMCA M103) refers to the use of DP footprint plots to record the vessel’s actual performance. These footprint plots, created on board, are of the vessel’s real station keeping performance in various thruster and vessel configurations and in different environmental conditions. Specification for DP Capability Plots, and IMCA M 220 – Guidance on operational activity planning (IMCA M140), can also be referenced.

The committee believe that a loss of position and heading should have been anticipated and therefore, serious consideration should have been given to securing the activities of the vessels industrial mission.

Related IMCA Guidance

Latest DP incidents

-

Simultaneous Operations

A DP Incident report highlighting the importance of maintaining focus during time on the DP desk

DPE 03/25

18 December 2025

Incident

-

DP drill scenario

DP emergency drill scenarios are included to assist DP vessel management and DPOs / Engineers and ETOs to conduct DP drills onboard.

DPE 03/25

18 December 2025

Drill Scenario

-

Know your settings

This Dynamic Positioning (DP) incident involved a DP equipment class 2 offshore supply vessel (OSV) during loadout operations from a drilling rig.

DPE 03/25

18 December 2025

Incident

-

Importance of familiarisation and paying attention

The importance of maintaining full attention during the operator's time on the DP desk can never be underestimated, or forgotten

DPE 03/25

18 December 2025

Incident

-

Worst case failure preparedness

Operators must be prepared for worst case failures

DPE 03/25

18 December 2025

Incident

The case studies and observations above have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity. Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators, and technical crew.

IMCA makes every effort to ensure both the accuracy and reliability of the information, but it is not liable for any guidance and/or recommendation and/or statement herein contained.

Any queries should be directed to DP team at IMCA. Share your DP incidents with IMCA online. Sign-up to receive DP event bulletins straight to your email.