Underwater ship husbandry has the highest fatality rate of any sector of commercial diving. Bill Chilton, Diving Manager at the IMCA and member of the IOGP’s Ships Husbandry Expert Group, sets out the key steps that the sector must take to reverse this trend and support diver safety.

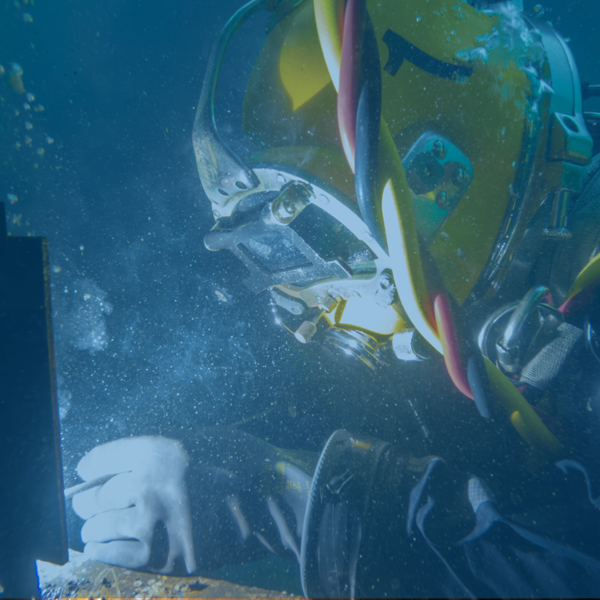

Underwater ship husbandry (UWSH) entails all aspects of the upkeep of the hull – including valves, sea chests, intakes, and discharges – and associated appendages – such as propulsion systems – of a ship or other floating structure.

Vessel owners and operators frequently have a need for UWSH. These projects normally comprise inspection, maintenance, repair, or cleaning – either to remove biofouling from the hull to prevent the growth of invasive non-native species, or to increase hydrodynamics and therefore reduce costs by minimising transit times fuel use.

Tragically, UWSH can also be extremely dangerous work.

Login / register to join the discussion

Comments

There are no comments for this article.