MAIB: Parted mooring rope leads to fatality

- Safety Flash

- Published on 6 February 2025

- Generated on 11 April 2025

- IMCA SF 02/25

- 3 minute read

Jump to:

The UK Marine Accident Investigation Branch has published Safety Digest 2/2024, consisting of lessons from recent Marine Accident Reports. IMCA has reviewed the report and passes on to members some of the incidents which we consider to be of interest. This is one of them.

What happened?

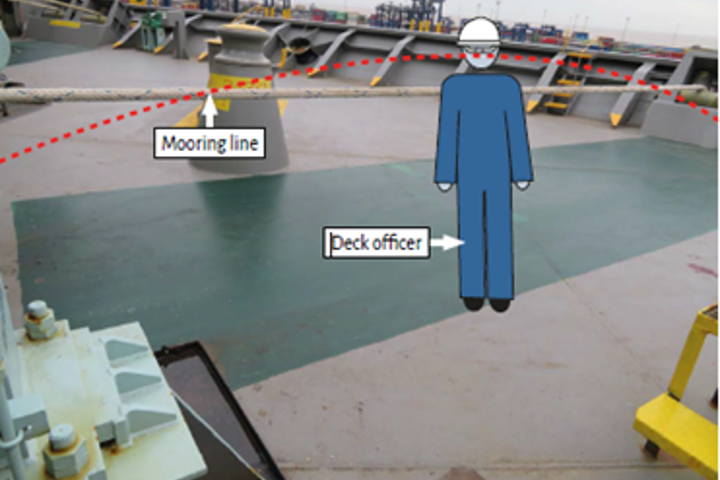

A deck officer was killed during mooring operations when a mooring rope parted and struck him on the head. The incident happened alongside on an ultra large container vessel. Cargo operations had been suspended due to very strong winds of over 50kts and the Master had taken the precaution of posting a crew member at the vessel’s forward and aft mooring stations to monitor and adjust its lines. A deck officer was making an inspection of the safety and security of the vessel, and on reaching the forecastle, went forward of the mooring winches to inspect the lines. While the officer was in this exposed position, standing close to a mooring line, a strong gust of wind hit the vessel and the rope parted close to the bollard ashore. On board, a bight of the mooring line flew up as the tension was released, striking the deck officer’s head. The ship’s crew quickly raised the alarm and paramedics attended the vessel. The injured deck officer was taken to hospital, but died a few days later.

Moored vessel

Warning sign

Incident location

Where the warning sign appears on the floor

What went wrong?

MAIB notes that mooring lines under tension in bad weather present a very significant risk to life and it must be assumed that they are liable to fail without warning.

- On this occasion the line parted just behind the mooring eye close to the jetty. Although the end of the rope did not snap back onto the forecastle, the sudden release in the line’s tension caused a bight of the rope on board to fly up and strike the deck officer.

- It is possible that the deck officer did not realise the risk involved of being stood in that place. The vessel’s mooring lines were almost new, still in good condition and no audible creaking or groaning was present to indicate imminent failure.

Lessons

- The entire forecastle mooring station had been identified as a snap-back zone;

- Additional measures to reduce risk could include fitting snap-back arrestors to mooring lines. These arrestors absorb the force within a parted line;

- STOP THE JOB!! The vessel operator in this case also introduced a campaign to encourage crew members to challenge colleagues who they observed as about to put themselves at risk.

Members should refer to:

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of the entire offshore industry.

The effectiveness of the IMCA Safety Flash system depends on the industry sharing information and so avoiding repeat incidents. Incidents are classified according to IOGP's Life Saving Rules.

All information is anonymised or sanitised, as appropriate, and warnings for graphic content included where possible.

IMCA makes every effort to ensure both the accuracy and reliability of the information shared, but is not be liable for any guidance and/or recommendation and/or statement herein contained.

The information contained in this document does not fulfil or replace any individual's or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.

Share your safety incidents with IMCA online. Sign-up to receive Safety Flashes straight to your email.